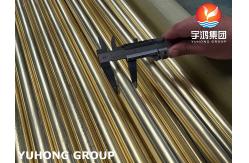

ASTM B111 ASME SB111 C68700 Aluminum Brass Tube For Heat Exchanger

|

|

ASTM B111 ASME SB111 C68700 Aluminum Brass Tube for Heat Exchanger

Description

It has high strength and hardness, good plasticity, and can be processed under pressure in cold and hot states. It has good corrosion resistance to seawater and brine, and resistance to impact corrosion, but it has the tendency of dezincification and corrosion rupture. Used for ships and other condensing pipes and other corrosion-resistant parts.

Chemical Composition

Mechanical Properties

Equivalent Grade of C68700

Characteristic

The pressure of Tin imparts to the alloy good corrosion resistance in a moderately polluted river water and clean seawater, either stagnant or slow moving (upto about 2 mtrs/sec.). The most common and wrought form is tube for heat exchange equipment. Guide to the selection of tube material:Clear river, Lake or Canal Water.a.

Dissolved salts more than 2000 ppm.b. Chloride less then 20 ppm.c. H2S and Ammonia is less than 1 ppm.d. Suspended solids less than 25 ppm.e. For temperature more than 2000C and less than 4500 C.Permissible average velocity of water 1.8-2.0 meters/sec.

Application

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Cold Finished ASME SB111 C44300 Copper Alloy Tubeb |

|

ASME SB111 / ASTM B111 C71640 (CuNi 70/30, CW353H),Copper Nickel Alloy Steel Tube / Condenser Tube |

|

ASTM B111 / ASME SB111 C68700 Aluminium Brass Tube |

|

Copper Nickel Alloy Tube ASTM B111 C70600 / CuNi10Fe1Mn, Heat Exchanger / Condenser/Cooling Application |

|

ASTM B111 C71500 Copper Nickel Alloy Seamless Tube for Heat Exchangers |

|

ASTM B111 C68700 Seamless Copper Alloy Tube for Heat Exchangers |