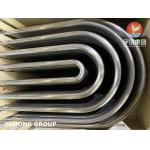

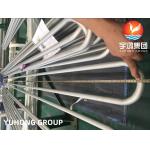

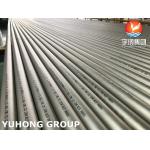

ASME SA213 Alloy Seamless Steel T9 Bend U Boiler Tubes

|

|

Specifications

Alloy Steel T9 EFW Tubes created in ostensible or least divider thickness for high temperature administration.SA213 T9 seamless tube with long length are accessible in hot moved condition up to 22.5m. Consistent ferritic combination steel T9 tube can be provided to meet unique surface prerequisites and additionally close measurement and divider thickness resilience.

ASME SA213 T9 alloy steel seamless tube is emphatically prescribed to utilized in an assortment of plants and procedures over the globe including refineries, control plants, petrol-synthetic plants, high and very high temperature lines, refining, oil field administrations, and so on.

Test Required Bend U tube Corrosion Test Chemical Analysis Mechanical Tests: Flattening test, Flaring test, Flange test, Hardness Test and Hydrostatic test Reverse-bend and Re. flat tests Eddy Current Testing Hydrostatic Testing Air Under Pressure Test Visual Inspection

Chemical Composition K90941

Mechanical Property K90941

Pharmaceutical Equipment Power Generation Sea Water Equipment Petrochemicals Pressure Vessel Heat Exchangers / Condensers / Boiler Oil and Gas Processing Specialty Chemicals General Engineering Pulp and Paper Industry

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

ASTM B163 Incoloy 800HT UNS N08811 Bright Surface Nickel Alloy Tube |

|

ASME SB163 UNS N04400 / Monel 400 Nickel Alloy Seamless Heat Exchanger Tube |

|

UNS NO6625/Din 2.4856/ASTM B444 Inconel 625 U Bend Tube Chemical Process Equipment NDT Available |

|

ASTM B622 / ASME SB622 Hastelloy C22 (UNS NO6022 ) Seamless Tube, Heat Exchanger /Boiler Application |