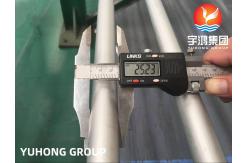

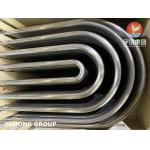

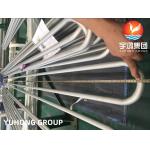

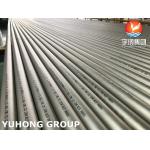

ASTM B444 Alloy 625 (UNS N06625) Seamless U Bend Tube Heat Exchanger Tube

|

|

ASTM B444 Alloy 625 (UNS N06625) Seamless U Bend Tube Heat Exchanger Tube N06625 Alloy Steel Heat Exchanger Tube metallographic structure: The microstructure of this alloy in the solid solution state is an austenitic matrix with a small amount of TiN, NbC, and M6C phases. After long-term aging at 650~900 ℃, the precipitated phases are γ',δ, M23C6 and M6C. N06625 Alloy Steel Heat Exchanger Tube Process Performance and

Requirements: N06625 Alloy Steel Heat Exchanger Tube Application 1.Components of organic chemical processes containing chlorides, especially when using acidic chloride catalysts; 2.Cooking and bleaching tanks used in the pulp and paper industry; 3.The absorption tower, reheater, flue gas inlet baffle, fan (wet), agitator, guide plate, and flue in the flue gas desulfurization system; 4.Used to manufacture equipment and components for sour gas environment;Acetic acid and acetic anhydride reaction generator;Sulfuric acid condenser, etc. N06625 Alloy Steel Heat Exchanger Tube Main specifications: Chemical Composition of UNS N06625 / Inconel 625 Heat Exchanger Tube

Mechanical Properties of ASTM B444 Inconel 625 Alloy Steel Heat Exchanger Tube Typical room temperature Tensile Properties of Annealed Material (Representative Tensile Properties, bar, 1800° F anneal)

Specifications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: UNS N06625 Seamless U Bend Tube Alloy 625 U Bend Tube U Bend Seamless Tube |

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

ASTM B163 Incoloy 800HT UNS N08811 Bright Surface Nickel Alloy Tube |

|

ASME SB163 UNS N04400 / Monel 400 Nickel Alloy Seamless Heat Exchanger Tube |

|

UNS NO6625/Din 2.4856/ASTM B444 Inconel 625 U Bend Tube Chemical Process Equipment NDT Available |

|

ASTM B622 / ASME SB622 Hastelloy C22 (UNS NO6022 ) Seamless Tube, Heat Exchanger /Boiler Application |