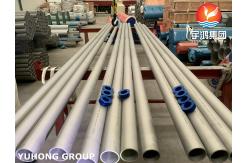

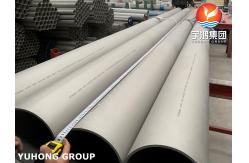

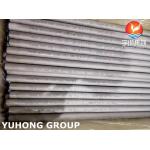

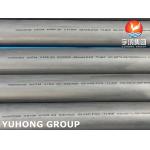

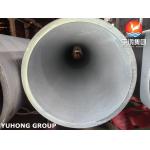

Super Duplex Steel Seamless Pipe ASTM A790 UNS S32750 Acid Resistant

|

|

Super Duplex Steel Seamless Pipe ASTM A790 UNS S32750 Acid Resistant

ASTM A790 S32750 Seamless Pipe is a super duplex stainless steel designed for applications which demand exceptional strength and corrosion resistance. Alloy 2507 has 25% chromium, 4% molybdenum, and 7% nickel.

(UNS S32750) Duplex stainless steel has strong strength and corrosion resistance, and is mainly used in chemical processing, petrochemical and subsea equipment. It has strong resistance to chloride corrosion, high thermal conductivity and low thermal expansion coefficient. Higher chromium, molybdenum and nitrogen content make it has a high ability to resist pitting corrosion, crevice corrosion and general corrosion.

Its impact strength is also very high. 2507 alloy is not suitable for use in a temperature environment higher than 570 ° C. Its toughness will decrease if it is in such an environment for a long time.

Chemical Composition of S32750

PMI:

Workmanship, Finish, and Appearance

Ordering Information

Duplex S32750 Pipe Weight Chart

Super Duplex 2507 Pipe Equivalent Material

Duplex Stainless Steel Features

Duplex stainless steels have Austenitic and Ferritic stainless steel microstructure, and possess properties in two groups stainless steel, however, there are different.

Versus Austenitic

Versus Ferritic

APPLICATIONS:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASME A789 S31803 Seamless Tube 25.4*1.24*11800MM Duplex Stainless Steel Tubes |

|

Duplex Stainless Steel Pipe, ASTM A790 , ASTM A928 , S31803 , S32750, S32760, S31254 , 254Mo, 253MA |

|

Duplex Steel Pipes , Super Duplex Pipes, A789, A790 , A928 S31803(2205) S32750 (2507) S32760 |

|

Super Duplex Stainless Steel Pipes, EN 10216-5 1.4462 / 1.4410, UNS32760(1.4501), Pickled & Annealed, ,20ft |

|

ASTM A790 / ASME SA790 S31803 Duplex Stainless Steel Pipe |

|

ASTM A790 duplex steel seamless pipe, UNS S31803 / S32205 (Duplex 2205), Thick Wall thickness |