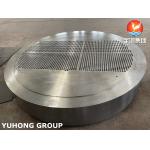

STAINLESS STEEL BAFFLE PLATE FLANGES, TUBESHEET,DISC FOR HEAT

EXCHANGER

YUHONG GROUP are professional for "Tubesheet " for “Shell & Tube Heat

Exchanger” application, we are available in many shapes, sizes and

have been used in industry for over 20 years. In our group we are

various sub design types: Fixed, U-tube and Floating tubesheet.

Variations of all can be denoted as type “E”, “F”, “G”, “H”, “J”,

“K” or “X”. The main applications are where high

pressure/temperatures are key considerations. Loosely, general

designs consist of the/an outer shell in which resides a tube

bundle (these can be configured as finned, plain etc) sealed at

each end by a tube sheet which isolates the tubes and the outer

shell. Shell & tube heat exchangers have the capability to

transfer large amounts of heat at low(er) costs. This, in

principle, down to both design simplicity and effectiveness – large

tube surface for reduced weight, volume of liquid and importantly

floor space. Whilst there is a wide variety to choose from there

are certain key components similar in all. Tubesheets have tubes

attached to them within the body or “shell” of the heat exchanger.

The tubes allow the movement of a given medium (gas/fluid) through

the shell chamber stopping it mixing with a second fluid medium

that lies outside these tubes. As long as there is a temperature

difference between these, in effect, the two flow past one another

exchanging heat without ever mixing. Tubesheets can be fixed or

floating dependent on the application the heat exchanger is

designed for.Tubesheets are a critical component of the final

design. There are a multitude of materials they can be manufactured

from. Material selection is made after careful consideration as it

is in contact with both fluids. It must therefore have the

necessary corrosion resistance, electromechanical and metallurgical

properties associated for its given working environment.The

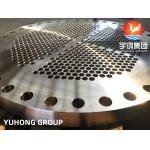

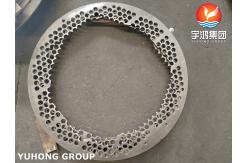

tubesheets themselves contain holes drilled into them. This, in a

given, very specific design configuration, at very precise

locations with critical tolerances. The amounts of holes can range

from a few to thousands. These pattern or “pitch” holes are

relative to each other tubesheet within the shell. This pitch

changes tube distance, angle and flow direction. These parameters

have been varied to maximize the heat transfer effectiveness.

Because these tubesheets are the main, critical, internal

components YUHONG GROUP manufactures directly to OEM drawings

issued files.

YUHONG GROUP considerable experience in this highly specialized

area means that whatever the requirement, whatever the timescale,

we have the technical, in house experience and know-how to approach

a given task, deliver on time and in budget. This is why the

company is entrusted to manufacture to key, blue chip clients

across the globe.

Materials: Carbon, Stainless, Duplex, Aluminum Bronze, Copper

Alloys, Naval Brass, Copper Nickel, Pure Copper Super Duplex,

Ni-Alloys, Exotic materials, and others as sought

| Carbon & Low Temperature | Chromiun | Stainless & Duplex | Copper& Bronze | Titanium | Ni-Alloy |

| A105 /A105N | A182-F1 | A182-F304 | A182-F347H | SB171-C70600 | SB381-GR.F1 | B564-NO2200 |

| A516-GR.70 | A182-F11 | A182-F304L | A182-F904L | SB171-C71500 | SB381-GR.F3 | B564-NO6022 |

| A350-LF2 | A182-F12 | A182-F304H | A182-F44 | SB171-C71520 | SB381-GR.F5 | B564-N10276 |

| | A182-F22 | A182-F304N | A182-F51 | SB171-C44300 | | B564-NO4400 |

| | A182-F5 | A182-F309S | A182-F53 | SB171-C68700 | | B564-NO6600 |

| | A182-F9 | A182-F310S | A182-F55 | SB171-C71640 | | B564-NO6601 |

| | A182-F91 | A182-F310H | A182-F60 | | | B564-NO6625 |

| | | A182-F316 | | | | B564-NO8800 |

| | | A182-F316L | | | | B564-NO8810 |

| | | A182-F316Ti | | | | B564-NO8811 |

| | | A182-F316H | | | | B564-NO8825 |

| | | A182-F317L | | | | B564-N10665 |

| | | A182-F321 | | | | B564-N10675 |

| | | A182-F321H | | | | B160-NO2201 |

| | | A182-F347 | | | | B462-NO8020

|