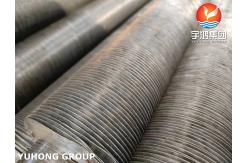

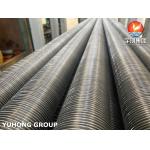

Embedded Finned Tube A179 Base Tube With Aluminum Fins for Cooling Systems

|

|

Advantages of Embedded Finned Tubes:

Manufacturing Processes for Embedded Finned Tubes:

Applications

|

| Product Tags: A1060 Carbon Steel Finned Tube Petroleum Chemical Finned Tube ASTM A179 Embedded Fin Tube |

|

ASTM A106 GR.B Carbon Steel Seamless Pipe Solid Fin tube For Furnace |

|

ASTM A376 TP347H solid Spiral High Frequency weld HFW Fin Tube With 11Cr |

|

ASTM A213 T9 Studded Alloy Steel Seamless Tube For Air Heaters And Economizers |

|

ASME SA209 TP304 Stainless Steel Embedded Fin Tube Fin Type G With Aluminum 1060 Fin |

|

Alloy Steel P22 High Frequency Welded Finned Tube For Heat Recovery |

|

Nail Head Tube Studded Tube For Petrochemical Industry |