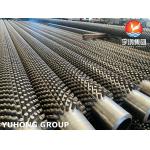

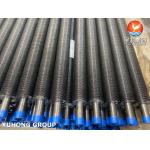

ASTM A335 Grade P9 Alloy Steel Seamless Pipe Studded Fin Tube And Pipe

|

|

ASTM A335 P9 Alloy Steel Studded Pipe Fin Tube Heat Exchanger Tube

Studded Pipe also called studded tubes, Nailhead Pipe or stud Pipe. It is one type of High HFW / Frequency Welded fin tube. Studded pipes are used as an alternative to finned tubes in heat exchangers mainly in the petrochemical industry where the surface is exposed to particular corrosion and aggression by gasses and vapors. This type fin tube can improving heat transfer efficiency much more than bare tube. Because of their relatively thicker Cross-section as compared to fins, Studded pipe is one of the mechanically Strongest extended-surfaces Available.

Base pipe/tube material Stainless steel: ASME SA213/ASTM A213, ASME SA249/A249 ,ASME SA312/A312: TP304,304L, TP304H, TP310S, TP310H, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321,TP321H, TP347, TP347H, TP904L Duplex/Super Duplex Steel: ASME SA789/A789 , ASME SA790/A790: S31803, S32205, S32750, S31500, S32304, S32900 Carbon Steel: ASME SA106/ASTM A106 Gr B, Gr C, ASME SA179/ASTM A179, ASME SA192/ASTM A192, ASTM A214, ASTM A210 Gr.A1 Alloy Steel: ASME SA213/ASTM A213 T1, T11, T12, T22, T23, T5, T9, T91, T92 ; ASME SA335 /ASTM A335 P1, P11, P12, P22, P23, P5, P9 , P91, P92 , 16Mo3, 15Mo3, 13CrMo-4, 12Cr1MoVG. Nickel Alloy Steel Grade:Hestalloy:C-276, C-4, C-22, C-2000, X, B-2, B-3, G-30, G-35. Monel:400,401, 404, R-405, K500. Inconel:600, 601, 617, 625, 690, 718, 740, X-750. Incoloy:800, 800H, 800HT, 825, 840. Pure Nickel:Ni-200, Ni-201, Ni-270. NS Alloy:Ns 1101, NS1102, NS1103,NS3105. Copper Alloy Steel: ASTM B111(70400, C70600, C71500, C71640, C68700, C44300)

Fin material: Alloy Steel , Stainless Steel , Carbon Steel . Stainless steel High Frequency Welded fins tube, carbon steel High Frequency Welded fins tube, Duplex High Frequency Welded fins tube Super Duplex High Frequency Welded fins tube, Air cooler fins tube, Air preheater fins tube. Extruded fins tube, Serrated fin tubes

Specification of studded pipe A335 alloy steel finned pipe Base pipe O.D: 15.88-219.1mm Fin height: 6-50mm Fin thickness: 0.3-3.0mm Fin pitch: as customer's request. End: Plain Ends, Beveled Ends No fin area on both side: As Customer's request and drawing

Alloy Steel Chemical Compositions

Advantages of Studded Tubes 1. As the pin rib of the studded tubes is a cantilever structure with a compact structure, the pin rib will vibrate under the impact of the air flow, making it difficult to accumulate soot. 2. due to the strong turbulent flushing of flue gas, the studded tubes heat exchange element has high heat transfer efficiency and strong self ash removal capability.

Application The mainly applications for studded tubes is the process heat recovery of the petrochemical industry, in areas of convection ovens, vacuum generators for chemical processing, specially used in petroleum applications. Studded pipes high resistance in the harsh environments, such as sections of Sulfuric Acid atmospheres, makes it very useful for the industries mentioned.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: ASTM A335 Alloy Steel Pipe Alloy Steel Seamless Fin Pipe Grade P9 Finned Tube | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Customized Length U Bend Fin Tube In Carbon Steel 16-219mm Diameter For Industrial |

|

ASME SA209 TP304 Stainless Steel Embedded Fin Tube Fin Type G With Aluminum 1060 Fin |

|

Alloy Steel P22 High Frequency Welded Finned Tube For Heat Recovery |

|

Studded Fin Tube HFW Fin Tube Furnace Application |

|

Carbon Steel Embedded G-Type Fin Tube ASTM A210 Grade A1 Al 1060 |

|

ASTM A335 P9 With 11Cr Studded Tube For High Temperature Service |