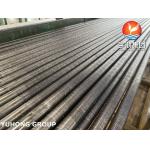

Embedded Finned Tube SA249 TP304 With Aluminium 1060 G-Fin, for

Heat Exchanger Thermal Equipment

What is ASME SA249 TP304 Fin Tube?

It is a kind of stainless steel tubing with fin structure, mainly

composed of ASME SA249 TP304 (stainless steel) tube and aluminum

fins. Finned tube is a type of tubing product that increases the

heat transfer area by machining a finned structure on the surface

of the tube.

ASME SA249 TP304 is a commonly used stainless steel material with

good corrosion resistance and mechanical properties. It is suitable

for applications in high temperature and corrosive environments

such as chemical, petroleum, pharmaceutical and food processing

industries.

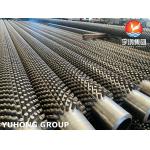

Aluminum fins are a material with good thermal conductivity. By

welding the fins to the surface of the stainless steel pipe, the

heat transfer area of the pipe can be effectively increased and the

heat transfer efficiency can be improved. This makes ASME SA249

TP304 with AL finned tubes widely used in thermal equipment such as

heat exchangers, coolers and heaters.

Customization Parameters

If you're sourcing or designing this product, key specs to define

include:

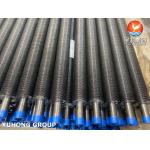

Tube OD and wall thickness (e.g., 25.4 mm OD × 2 mm wall)

Fin height and thickness (e.g., 15 mm height × 0.4 mm thickness)

Fin pitch (fins per inch or mm)

Tube length

Groove depth and profile

Features of ASME SA249 TP304 fin tube

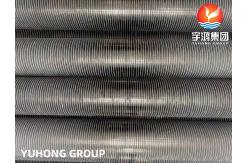

- High heat transfer efficiency: through the finned structure, the

heat transfer area of the pipe is increased and the heat transfer

efficiency is improved, thus reducing the size and cost of the

equipment.

- Good corrosion resistance: ASME SA249 TP304 stainless steel has

good corrosion resistance and is suitable for heat transfer and

heat exchange in a wide range of corrosive media.

- Lightweight design: Aluminum fins are lightweight, which reduces

the weight of the equipment and improves its transportation and

installation efficiency.

- ASME SA249 TP304 with Aluminium finned tubes are widely used in

thermal equipments such as heat exchangers, coolers, heaters in

chemical, petroleum, pharmaceutical, food processing and other

industries. They can provide efficient heat transfer and heat

exchange performance in high temperature and corrosive environments

to meet the needs of industrial production.

Chemical Composition OF ASME SA249 TP304

| Grade | C | Si | Mn | Cr | Ni | S | P | Fe |

|---|

| TP304 | 0,08 | 1,0 | 2 | 18 – 20 | 8 – 11 | 0,03 | 0,045 | Bal. |

Mechanical Propertie OF ASME SA249 TP304

| Grade | Tensile Strength (Mpa) | Yield Point (Mpa) | Elongation (%) |

|---|

| TP304 | 515 | 205 | 35 |

Physical Properties OF ASME SA249 TP304

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (μm/m/°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100°C (J/kg.K) | Electrical Resistivity (nΩ.m) |

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C |

| 304 | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |

Application:

- Air-Cooled Heat Exchangers (ACHE)

- Waste Heat Recovery Systems

- HVAC Systems

- Dry Cooling Towers

- Furnace and Kiln Heat Exchangers

- Cryogenic and LNG Applications

- Food & Beverage Processing

- Chemical & Pharmaceutical Plants