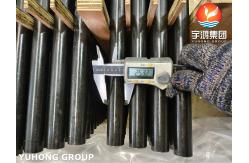

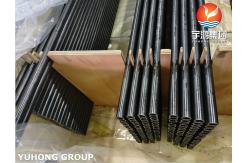

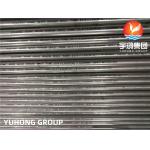

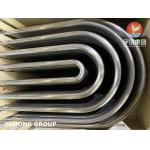

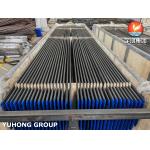

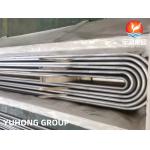

ASTM A213 T9 Alloy Steel Seamless U Bend Tube Heat Exchanger Tubing

|

ASTM A213 T9 ALLOY STEEL SEAMLESS U BEND TUBE HEAT EXCHANGER TUBING

ASTM A213 T9 Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, Heat-Exchanger Tubes. ASME SA213 T9 Tube is useful in modern power devices that operate

with high efficiency to guarantee their long-term, e and

trouble-free operation. ASTM a213 T9 Tube is used to heat water

that is circulated through a closed loop piping system for general

facility and service water heating. Low-temperature systems

generally operate below 200°C. Medium-temperature systems generally

operate between 200 and 250°C. SA213 T9 Boiler Tube is made from

heat resisting carbon and low alloy steel which can withstand the

loads at various pressures and temperatures. Boiler tubes is useful

for parts of energy type equipment’s like boilers, super heaters,

economizers, heat exchangers, etc. T9 boiler tubes are manufactured

as hot rolled or cold drawn with welded and seamless manufacturing

process. ASTM A213 T9 Grades containing the letter H in their designation

have requirements different from those of similar grades not

containing the letter H. These different requirements provide

higher creep-rupture strength than normally achievable in similar

grades without these different requirements. ASTM A213 T9 tubes

shall be made by the seamless process and shall be either hot

finished or cold finished, as specified. Grade TP347HFG shall be

cold finished. Heat treatment shall be done separately and in

addition to heating for hot forming. The ferritic alloy and

ferritic stainless steels shall be reheated. On the other hand,

austenitic stainless steel tubes shall be furnished in the

heat-treated condition. Alternatively, immediately after hot

forming, while the temperature of the tubes is not less than the

minimum solution temperature, tubes may be individually quenched in

water or rapidly cooled by other means. Tension test, hardness

test, flattening test, and flaring test shall be done to each tube.

Also, each tube shall be subjected to the nondestructive electric

test or hydrostatic test.

Overview of ASTM A213

A213 is often called chrome moly tube because of the chemical makeup of Molybdenum (Mo) and Chromium (Cr). Molybdenum increases the strength of steel as well as the elastic limit, resistance to wear, impact qualities, and hardenability. Moly increases the resistance to softening, restrains grain growth and makes chromium steel less susceptible to embrittlement. Moly is the most effective single additive that increases high temperature creep strength. It also enhances the corrosion resistance of steel, and inhibits pitting. Chromium (or chrome) is the essential constituent of stainless steel. Any steel with 12% or more Chrome is considered stainless. Chrome is virtually irreplaceable in resisting oxidation at elevated temperatures. Chrome raises the tensile, yield, and hardness at room temperatures. The composition chrome moly alloy steel Pipe make it ideal for use in power plants, refineries, petro chemical plants, and oil field services where fluids and gases are transported at extremely high temperatures and pressures.

Features of ASTM A213 T9 Alloy Steel Heat Exchanger Tubes

A213 T9 Equivalent Material Grade

Mechanical Properties

Chemical Composition

Tolerance of SA213 T9 Steel Tubing

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Alloy Steel Seamless Heat Exchanger Tubing T9 Alloy Steel U Bend Tube Cold Rolled U Bend Tube |

|

ASTM A179 Seamless High Precision Heat Exchanger Tubes Oil Coated Surface |

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

Seamless Carbon Steel Heat Exchanger Tube U Bend Tube ASTM A179 A210 A1 |

|

ASME SA213 TP347 TP347H Stainless Steel U Bend Tube ET/HT for Heat Exchanger Tube |

|

ASTM A213 TP304L Austenitic Stainless Steel Seamless U Bend Tube |