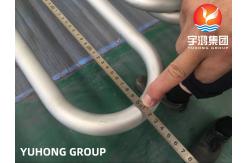

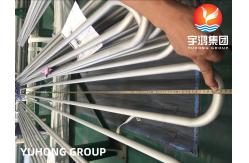

Inconel 625 u bend tube ASTM B444 UNS N06625 for Aerospace Industry

|

|

Seamless U Bend Tube ASTM B444 Inconel 625 UNS N06625 Heat Exchangers

What is Inconel 625?

ASTM B444 is the standard specification for nickel-chromium alloy tubing, which consists of a nickel-chromium-molybdenum-niobium alloy. The main reason why these alloys are considered very useful in the manufacture of high quality tubing products is that it has high resistance to oxidation and corrosion and has a high melting point in both water and high temperature applications. The nickel based alloys are very ductile and therefore can be easily plated and welded, thus making them suitable for a variety of industries where extreme and harsh temperatures are important factors.ASTM B444 Seamless and ASTM B444 Seamless Tubing are suitable for use in aerospace industry piping systems, aviation jet engine exhaust systems, engine thrust reserve systems, specialized seawater equipment, chemical process equipment, etc.

Chemical Composition:

Inconel 625 Mechanical Properties & Heat Treatment

Mechanical properties of alloy N06625 grade 1 (annealed) pipe: tensile strength ≥ 120 ksi [827 MPa]; yield strength ≥ 60 ksi [414 MPa]; elongation within 2″ ≥ 30%. Mechanical properties of alloy N06625 Grade 2 (solution annealed) pipe: tensile strength ≥ 100 ksi [690 MPa]; yield strength ≥ 40 ksi [276 MPa]; elongation within 2″ ≥ 30%. Annealing heat treatment shall be carried out at a temperature of not less than 1600°F [871°C]. Solution annealing heat treatment shall be performed at a temperature of not less than 2000°F [1093°C] with a subsequent stabilized annealing temperature of at least 1800°F [982°C] to increase sensitivity.

Equivalent of Inconel 625

Heat Treated Materials

Typical properties of Inconel 625

Applications:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: UNS N06625 U Bend Tube Inconel 625 Seamless U Bend Tube Annealed Heat Exchanger U Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM A213 TP304, TP304L , TP316L , TP321 , TP310S, TP347H , TP317L ,16 BWG 20FT Heat Exchanger Tube |

|

Heat Exchanger Stainless Steel Seamless Tube , ASTM A213, ASME SA213 , TP304/304L , TP316/316L , TP321/321H, TP310S |

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

ASTM B163 Incoloy 800HT UNS N08811 Bright Surface Nickel Alloy Tube |

|

UNS NO6625/Din 2.4856/ASTM B444 Inconel 625 U Bend Tube Chemical Process Equipment NDT Available |