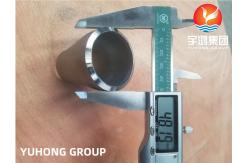

Buttweld ASME SB366 N06600 2.4816 Inconel 600 Concentric Reducer

|

|

Buttweld ASME SB366 N06600 2.4816 Inconel 600 Concentric Reducer

What Is UNS N06600 Pipe Fittings?

One of the most widely used alloys in the nuclear industry is Inconel 600. The reason why this alloy is popular across several industries amounts to many facts. Firstly, the Inconel 600 Pipe Fittings can operate at a wide temperature range. From a temperature as high as 2000° F to cryogenic temperatures. As the alloy contains about 70% nickel in its alloy, the ability to withstand high temperatures is something that is inherent in the Inconel 600 Fittings. The corrosion resistance properties of alloy 600 are widespread over several compounds and solutions.

Our Inconel 600 Pipe Fittings offers excellent performance in several critical environments. We are one of the top producers of different ASTM B366 UNS N06600 Inconel Alloy 600 Pipe Fittings in China, known for their accurate dimensions and durability. Inconel 600 Equivalent Material

Inconel 600 Chemical Analysis

Inconel 600 Mechanical Properties

Inconel 600 Physical Properties

Nickel Alloy 600 Fittings Thickness Chart

Weight Chart of Inconel 600 Fittings

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

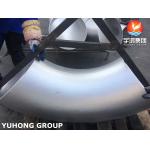

ASTM A403 WPS31254 Duplex Stainless Steel 254SMO Fittings 90 Degree LR Elbow |

|

ASTM A815 UNS S32750 Super Duplex Stainless Steel Fittings 90 Degree LR Elbow |

|

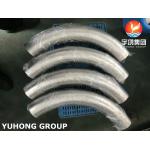

ASTM B366 UNS N08810 Alloy 800H Buttweld Fittings 180 Degree Return Bend |

|

EN 10253-2 1.4541 Large Diameter Butt Weld Fitting 90 Deg Elbow |

|

ASTM A815 UNS S31803 Duplex 2205 90° LR Elbow ASME B16.9 Buttweld Pipe Fittings |

|

ASTM A815 Duplex Steel UNS S31803 Buttweld Pipe Fitting ASME B16.9 5D Elbow |