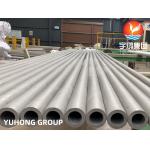

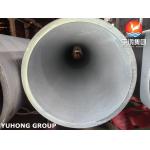

Duplex Stainless Steel Pipe ASTM A790 UNS S32205 Reactors Tanks

|

|

Duplex Stainless Steel Pipe ASTM A790 UNS S32205 Reactors Tanks

What is UNS S32205?

S32205 is a modern duplex stainless steel material combining austenitic and ferritic materials. It is known for its extremely high strength and resistance to stress corrosion cracking. These trademarks are approximately twice as strong as the austenitic and ferritic trademarks. It has better resistance and ductility than ferritic steels, but not up to the level of austenitic steels. Heat treatment is easy, but cold forming is difficult. Duplex (austenitic/ferritic) steel (Type 2205) containing 22% chromium has medium to high strength and superior resistance to general corrosion/stress, corrosion/cracking. It is generally used to make chemical processing equipment, pressure vessels and heat exchanger components. The alloy is resistant to chloride environments and chemical stress corrosion, and is approximately twice as strong as standard austenitic stainless steels. Requirements for higher mechanical strength / lighter weight, the alloy can be successfully used as a 300 series austenitic stainless steel replacement. s32205 easy to use many standard arc welding equipment for welding, but not recommended for oxyethylene block welding, due to the weld metal may present the phenomenon of carbonization. s32205 application planning application areas are: typical applications include oil and gas, chemical, electric power, and brewing industry. Widely used pumps, valves, flanges and piping systems. Martensitic stainless steel trademark is a group of corrosion-resistant and hardenable (using heat treatment) stainless steel alloys. Martensitic grades are pure chromium steels without nickel. They are magnetic, can be hardened by heat treatment, and are not as corrosion resistant as austenitic stainless steels. Martensitic grades are used primarily where hardness, strength and wear resistance are required.

Chemical Composition of ASTM A790 UNS S32205

Physical Properties of ASTM A790 UNS S32205

ASTM A790 UNS S32205 Heat Treatment

Heat Resistance of ASTM A790 UNS S32205

The high oxidation resistance property of Grade 2205 is marred by its embrittlement above 300°C. This embrittlement can be modified by a full solution annealing treatment. This grade performs well at temperatures below 300°C.

Duplex Stainless Steel Pipe Application:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASME A789 S31803 Seamless Tube 25.4*1.24*11800MM Duplex Stainless Steel Tubes |

|

Duplex Stainless Steel Pipe, ASTM A790 , ASTM A928 , S31803 , S32750, S32760, S31254 , 254Mo, 253MA |

|

Duplex Steel Pipes , Super Duplex Pipes, A789, A790 , A928 S31803(2205) S32750 (2507) S32760 |

|

Super Duplex Stainless Steel Pipes, EN 10216-5 1.4462 / 1.4410, UNS32760(1.4501), Pickled & Annealed, ,20ft |

|

ASTM A790 / ASME SA790 S31803 Duplex Stainless Steel Pipe |

|

ASTM A790 duplex steel seamless pipe, UNS S31803 / S32205 (Duplex 2205), Thick Wall thickness |