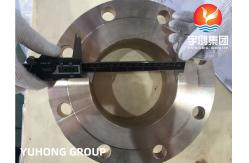

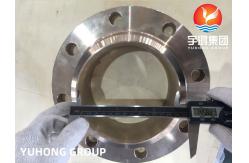

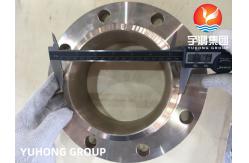

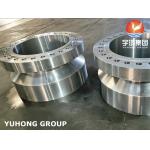

Copper Nickel Flange ASTM B151 UNS C70600 Heat Exchanger Application

|

Copper Nickel Flange ASTM B151 UNS C70600 Heat Exchanger Application

Overview

The modulus of elasticity (C71500 annealed) of the copper-nickel flange is 22,000 ksi (152 GPa). The yield strength (annealed) of the copper-nickel WNRF flanges is 15,000 psi (103 MPa).The density of ASME SA151 copper-nickel threaded flanges is 0.323 lb/in³ (8.94 g/cm3). The Poisson's ratio for copper-nickel threaded flanges (C71500 annealed) is 0.325. The pressure rating of these copper-nickel blind flanges is very important as it determines what kind of copper-nickel industrial flanges can be used, for what purpose and in which industry. Cu-Ni grade forged flanges are weldable and show resistance to scaling and very good corrosion resistance. ANSI B16.5 Cooney Ring Joint flanges show excellent resistance to corrosion (especially seawater), cavitation and erosion. Cu-Ni RTJ flanges show good weldability. ASTM A151 Cu-Ni threaded flanges are durable and, most importantly, they are inexpensive. They are used in process equipment, hydraulic lines, automotive components, underwater enclosures, marine hardware components, feedwater heaters, pump components, heating cables and air conditioning plants.

Characteristic

Copper-nickel alloys have excellent resistance to seawater corrosion, biofouling and resist attack by corrosion and erosion. The corrosion resistance of copper-nickel alloys is due to the

presence of a protective surface film of copper-nickel oxide, which

is firmly bound to the metal and virtually insoluble in water. This

oxide film protects the pipes from further attack. The protective

oxide film takes about three months to stabilise. It is therefore

recommended that newly made copper-nickel alloy pipes are not

exposed to corrosive environments. The corrosion rate in static

seawater is approximately 0.1 mm/year. Once a protective film has

formed, the corrosion rate is reduced to 0.01 mm/year. In acidic

environments (e.g. H2S) the corrosion rate increases sharply as the

sulphide ions destroy the protective oxide film.

Chemical Composition of B151 UNS C70600

Mechanical Properties of B151 UNS C70600

Equivalent Grades

Application

Offshore fire water systems Tubes for power plants and ships Hear Exchanger Condensers Pumps, valves, sheathing and fittings for ship hulls

|

|

ASME SA182 F904L Stainless Steel Slip On RF Flanges B16.5 |

|

ASTM A182 F53 WNRF Flange Class 150 To 2500 High Pressure Pipe Connection |

|

ASTM A182 F60 Weld Neck Flange AS2129 Australian Standards |

|

ASTM B564 Alloy600 UNS NO6600 Nickel Alloy Blind RF Face Flange Forging |

|

A105 Carbon Steel Heavy Barrel Nozzle Flange For Higher Pressure Applications |

|

ASTM A105 Carbon Steel Forged Flange BLRF SORF WNRF Black Painted |