ASME SA36 CARBON STEEL BAFFLE PLATE MIXING REACTOR SHIP BUILDING

|

ASME SA36 CARBON STEEL BAFFLE PLATE MIXING REACTOR SHIP BUILDING

Abstract

A baffle plate is a component used in various industrial applications to control the flow of fluids or gases. It is typically a flat or curved plate strategically placed within a system to alter or redirect the flow pattern. Baffle plates are often made from materials such as metal, plastic, or composite materials, depending on the specific application and operating conditions. The primary purpose of a baffle plate is to create turbulence or obstruction in the flow path, which can have several effects depending on the intended purpose:

It's important to consider factors such as fluid dynamics, pressure drop, and material compatibility when designing or selecting a baffle plate for a particular application. Consulting with engineers or industry professionals can help determine the optimal design and material selection for the intended

What is baffle plate?

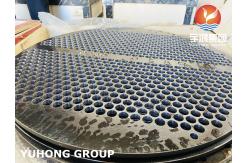

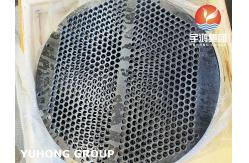

Baffles are components of shell and tube heat exchangers which are used to support and fix the tubes in a defined position. There are different types of baffle configurations. The most popular type is the perforated plate in the form of a segmented circle. The segmental baffles are arranged so that the segmented section faces are disposed opposite to each other along a bundle of tubes at specified interval. There are different types of baffle configurations. The most popular type is the perforated plate in the form of a segmented circle. The segmental baffles are arranged so that the segmented section faces are disposed opposite to each other along a bundle of tubes at specified interval. Baffle plate is widely used in shell and tube heat exchanger, boiler, pressure vessel, steam turbine, large central air conditioning,etc. The baffle sheet is mainly used for chemical containers, such as shell and tube heat exchanger, boiler, pressure vessel, condenser, central air conditioning, evaporator, water desalination with the function of supporting the tube bundle and improving heating efficiency. The material of metal makes it not only has the very strong rigidity, and has a great deal of heat conduction performance.

How baffles work?

Types of baffles:

YUHONG's Quality Control:

SA36 Chemical composition:

SA36 Mechanical Properties:

|

|||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Pressure Vessel Baffle Plate ASME SA-36 Baffle Plate |

|

ASME SA516 Grade70N Carbon Steel Baffle for Shell and Tube Heat Exchanger |

|

ASME SA336 F5N High Temperature And Pressure Alloy Steel Forging For Heat Exchanger Baffle |

|

EN 10025-2 S235JR Carbon Steel Baffle Tubesheet For Heat Exchanger |

|

Heat Exchanger Parts Pressure Vessel Baffle Plate SA387 GR.11 CL.2 A36 |

|

ASME SA516 Gr 70 Carbon Steel Baffle Plate For Heat Exchanger |

|

ASTM A182 Stainless Steel Baffle For Pressure Vessels |