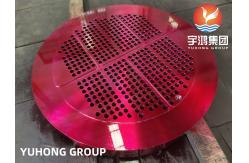

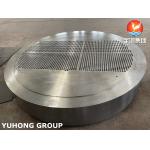

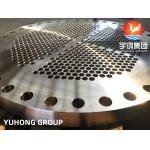

ASTM A182 F304 / 1.4301 Stainless Steel Tubesheet Heat Exchanger Component

|

|

ASTM A182 F304 / UNS S30400 / 1.4301 Stainless Steel Tubesheet Heat Exchanger Parts

A stainless steel tubesheet is typically a flat plate that contains holes where the tubes are inserted and then expanded or welded into place. Tubesheets are an essential component in heat exchangers, boilers, and other pressure vessels where tubes need to be sealed and supported securely. Stainless steel tubesheets are used in corrosive environments or applications where high temperature resistance is required. Stainless steel offers excellent corrosion resistance, durability, and strength, making it a popular choice for tubesheet material.

Specification

One of the most common heat exchangers in service within industrial

process applications is the “Shell & Tube Heat Exchanger”.

Shell & tube heat exchangers have the capability to transfer large amounts of heat at low(er) costs. This, in principle, down to both design simplicity and effectiveness – large tube surface for reduced weight, volume of liquid and importantly floor space.

Application Shell and tube heat exchanger is used in various industrial process applications because they can perform tasks such as: Removal of process heat

and feed water preheating. Cooling of hydraulic and lube oil.

Cooling of turbine, compressor, and engine. Water works, Shipbuilding industry, Petrochemical & Gas industry, Power industry, Valve industry and general pipes connecting projects etc.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: ASTM A182 Stainless Steel Tube Sheet F304 Stainless Steel Sheet Boiler Stainless Steel Tube Sheet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Normalized Carbon Steel Tubesheet Sa516 Gr.70n Heat Exchanger Component |

|

ASTM A182 Stainless Steel Baffle And Tubesheet For Heat Exchanger |

|

ASME SA516 Gr.70N Stationary Tubesheet Used In Heat Exchanger |

|

High Strength Steel Baffle And Tube Sheet Used In Heat Exchanger / Boiler / Air Conditing |

|

EN10028 1.4541 Stainless Steel Tube Sheet For Floating Head Exchanger Shell Heat Exchanger |

|

ASTM A182 F316L Stainless Steel Tubesheet For Heat Exchanger |