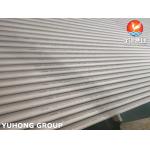

ASTM A213 TP321 Stainless Steel Seamless Tube Cold Drawn Low

Temperature Application SA213 Tp321 is a heat exchange tube specification made of 321

austenitic stainless steel. SA 213 specifies piping products for

heat exchangers of different material grades, including ferritic

and austenitic steels. Yuhong is a supplier of all kinds of

stainless steel pipes. The SA213 Tp321 material is special in that

it contains titanium in its composition, which reduces the density

of ASME SA213 Tp321, making it lighter. The addition of titanium also provides high corrosion resistance to

ASTM A213 Tp 321 pipe. Thanks to the addition of titanium, 321

stainless steel reduces the risk of intergranular corrosion present

in most high carbon steels. 321 stainless steel exhaust pipe lasts

longer at high temperatures. Therefore, 321 stainless steel

seamless tubes are used in heat exchangers and superheaters. These

pipes are available in different types such as 321 stainless steel

hoses that are easy to install and maintain. Applications for Type

321 stainless steel tubing can also be seen in boilers and

condensers. We manufacture high quality 321 SS tubing in different

sizes and types. Our SS 321 seamless pipe is suitable for small

size pipes with high precision. This corrosion resistant steel can

also be identified as 321 Cres Tubing. Our customers can also get

custom finishes for these pipes. If you have any questions about

product details or pricing, please contact us. ASTM A 213 321 Stainless Steel Tubing Mechanical Properties| NOMINAL OD | NOMINAL WALL | ULTIMATE KSI | YIELD KSI | ELONGATION |

|---|

| | | | | | | .188 and less | .016 and less | 75-120 maximum | | 35% | | | | 75-105 maximum | 30 min | | | | Over .016 | | | 35% | | | | | | | | Over .188 | .010 and | 75-115 maximum | 30 min | 35% | | Thru .500 | Less | | | | | incl | Over .010 | 75-105 maximum | | 35% | | | | | | | | Over .500 | All | 75-100 maximum | 30 min | 35% |

Stainless Steel 321 Tube Chemical Composition| WEIGHT % | NI | CR | MN | C | SI | S | P |

|---|

| MIN | 9.00 | 17.00 | | | | | |

|---|

| MAX | 12.00 | 19.00 | 2.00 | .080 | 1.00 | .030 | .045 |

|---|

SS 321 Tubes for sale| ASME SA213 TP321 Exhaust Tubing | 321 Stainless Steel Dom Tubing | | SS 321 Rectangular Tubing | SA 213 TP 321 Stainless Steel Hydraulic Tubing | | ASTM A 213 321 Stainless Steel Seamless Tubing | ASME SA213 TP321 Round Tubing | | ASTM A213 TP 321 EFW Tube | JIS SUS321 UNS S32100 High Precision Tubes | | SA 213 Gr 321 ERW Tube | SA213 TP321 Coil Tubing | | Stainless Steel 321 Electropolished Tubing | SS 321 12mm Tubing | | SA213 321 SS Small Diameter Tubing | ASTM A 213 321 Stainless Steel Elliptical and Oval Tubes | | JIS SUS321 UNS S32100 High Pressure Tubing | Stainless Steel 321 Heat exchanger Tubes | | Grade SA213 TP321 Cold Drawn Seamless Tubing | SA213 321 SS Condenser Tubes | | 321 Stainless Steel Instrument Tubing | SS UNS S32100 Sanitary Tube | | SA 213 TP 321 Stainless Steel Square Tubing | DIN 1.4541 Stainless Steel 321 1 inch Tube |

SA 213 TP 321 Stainless Steel Tubing SpecificationCheck Dimensions & sizes of 321 SS Welded Tubing| 321 | AMS 5557, 5570, 5576, 5645 | | 321 | MIL-T-8606, 8808, 8973 |

| Standard Specification | AMS 5557, 5559, AMS 5570, MI-L-T 8808, MIL-T-8606 | | ASTM A213 / ASME SA 213 | Standard Specification for 321 Stainless Steel Seamless

Superheater, Condenser, Hydraulic, Boiler and Heat-Exchanger Tubes | | Shapes | SA 213 TP 321 Stainless Steel Round, Rectangular, Square,

Hydraulic, Straight, "U" Shape, Coiled, Honed Tubes, Pan Cake Coils | | Manufacturing Type | Seamless / ERW / Welded / Fabricated / CDW / CDS / DOM / CEW / 100%

X Ray Welded | | Delivery Condition | Annealed and Pickled (AP), Polished, Bright Annealed (BA), Cold

Drawn, MF | | Surface Finish | BA, 2B, No.4, No.1, No.3, No.8, 8K, HL, 2D, 1D, Mirror Polished,

180G, 320G, 400G Satin/ Hairline, 400G, 500G, 600G or 800G Mirror

finish ASME SA213 TP321 Tubing or Custom Finish as per customer's

specification | | Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXH, SCH XXS,

SCH XS | | Standard | SUS, JIS, AISI, ASTM, GB, DIN, EN | | Relevant Standard | ASTM A213, ASTM A312, ASTM A269, ASTM A778, ASTM A554, ASTM A249,

ASTM A269, ASTM A270, ASTM A789, DIN 17456, DIN17457, DIN 17459,

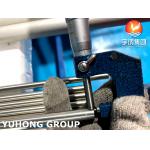

JIS G3459, JIS G3463, GOST9941, EN10216, BS3605, GB13296 | | Value Added Services | - Cutting

- Beveling

- Threading

- Polishing (Electro & Commercial)

- Draw & Expansion as per required Size & Length

- Destructive and Non Destructive

- Ultrasonic Testing

- Annealed & Pickled Bending

| | Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. | | END | Plain End, Beveled End, Treaded SS 321 Tube | | Processing Service | Bending, Welding, Decoiling, Punching, Cutting, Moulding | | Technique | ASTM A 213 321 Stainless Steel Cold drawn, Cold rolled, Hot rolled,

Extrusion Tube | | Tolerance | - Outer Diameter: +/- 0.2mm

- Thickness: +/- 10% OR as customer request

- Length: +/- 10mm

| | Marking | - Specification

- Material Grade

- Nominal Size

- Schedule or Wall Thickness

- Method of Manufacturing (Seamless / Welded)

- Heat Number

- Manufacturer’s Name or Custom Logo - on request

Marked Pipe Sample: 321 Stainless Steel 12" NB SCH 40S SEAMLESS

HEAT NO. XXXX | | Test Certificate | - DFARS compliant

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test

Certificates (MTC)

- 100% Radiography Test Report

- Raw Materials Certificate

- Third Party Inspection Report

- Fumigation Certificates

- Heat Treatment Charts

- HS Code Commercial Invoice

- Form A for Generalized System of Preferences (GSP)

- Manufacturer Test Certificate

- Moisture testing

- Surface roughness measurement

- Laboratory Test Certificate from Govt. Approved Lab

| | Stainless Steel 321 Tubing Packaging | Packed in PE Fabric Bundles or ply wooden box wrapped in plastic or

Standard seaworthy export packing or as per customers' request | | | | | Uses & Application | - Common industrial services (Petroleum, chemical, paper, fertilizer,

fabric, aviation and nuclear)

- Fluid, gas and oil industry

- Heat transmission and pressure service

- Construction and ornamental

- Boilers and Heat exchangers

- Decoration purpose, boiler, auto parts, medical device, food

industry, building materials)

|

Application: - Food processing equipment, especially beer brewing, milk processing

and wine making.

- Kitchen benches, sinks, sinks, equipment and appliances

- Building paneling, railings and decoration

- Chemical containers, including for transportation

- Heat exchanger

- Woven or welded screens for mining, quarrying and water filtration

- Threaded fasteners

- Spring

- Other

|