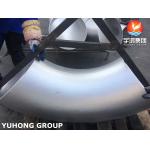

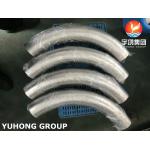

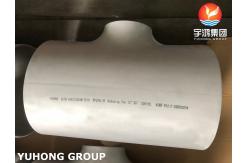

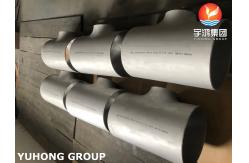

B16.9 Butt Weld Pipe Fittings , ASTM A403 WP304L-W Stainless Steel

Reducing Tee

Stainless steel tees are available in different types based on the connection method

and flow direction. Equal Tee: all three openings have the same size, allowing an equal

flow distribution between the branches. Reducing Tee: It has different-sized outlets, providing the ability to branch

off into pipes of different sizes.

Stainless steel tees can be connected in various ways, including

welding, threading, or through mechanical connections such as

flanges. The connection method depends on the specific requirements

of the piping system and the types of fittings being used. They are

commonly used in industries such as oil and gas, petrochemical,

chemical processing, food and beverage, pharmaceuticals, and water

treatment. They are suitable for both high-pressure and

high-temperature applications.

Stainless Steel ASTM A403 WP304L Fittings Specifications | ASTM A403/ ASME SA403 |

|---|

ASTM A403 WP304L Pipe fittings Types | ASTM A403 Grade WP304L Buttweld Fitting ASTM A403 WP304L Stainless Steel Seamless Fittings Stainless Steel ASTM A403 WP304L ERW Fittings ASTM A403 WP304L SS Welded Fittings SS WP304L Fabricated Pipe Fittings ASTM A403 Grade WP304L Bevel Ends Pipe Fittings

|

|---|

ASTM A403 WP304L WP304L Pipe Fittings Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560,

BS10 |

|---|

ASTM A403 WP304L Pipe Fittings size | ASTM A403 WP304L Seamless Butt Weld Fittings: 1/2" - 10"

ASTM A403 WP304L Welded Butt Weld Fittings: 1/2" - 48" |

|---|

Stainless Steel WP304L Fittings Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH

120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

|---|

| ASTM A403 WP304L Pipe Fittings | Tee, Reduceing Tee, Elbow, Cap, Con. Reducer, Ecc. Reducer |

|---|

ASTM A403 WP304L Fittings Manufacturing process | Push, Press, Forge, etc. |

|---|

ASTM A403 WP304L Buttweld Fitting Connection | Welding |

|---|

Fitting End | Threaded, Welding |

|---|

Buttweld Fitting Types | Seamless / Welded |

|---|

Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

|---|

WP304L Stainless Steel Buttweld Pipe Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc

|

|---|

Application & uses of Industrial A403 WP304L Fittings | Fittings To Connect Pipe & Tubes in Petroleum, Power, Chemical,

Construction, Gas, Metallurgy, Shipbuilding etc Schedule 10 fittings are an economical alternative for

lower-pressure applications. Schedule 40 fittings have a thicker wall for higher-pressure

applications.

|

|---|

We provide Material Test Certificates (MTC) as per EN 10204 3.1 and

EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 |

|---|

Nickel Alloy

ASTM / ASME SB 336 UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201 ),

UNS 4400 (MONEL 400), UNS 8020 (ALLOY 20 / 20 CB 3, UNS 8825

INCONEL (825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS

6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276)

Stainless Steel

ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N,

304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel

ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S

32760.

Carbon Steel

ASTM / ASME A 234 WPB, WPC

ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 &

WPHY 70.

Alloy Steel

ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP

91

Standard | ASTM A403 /ASME SA403 | WP-W | ANSI B16.9/MSS SP-43 | KS : KOREAN INDUSTRIAL STANDARDS | KS B 1522: Steel Butt Welding Pipe Fittings for Oidinary

use, Fuel Gas

KS B 1541: Steel Butt Welding Pipe Fittings

KS B 1542: Steel Socket Welding Pipe Fittings

KS B 1543: Steel Plate Butt Welding Pipe Fittings | JIS : JAPANESE INDUSTRIAL STANDARDS | JIS B 2311: Steel Butt Welding Pipe Fittings for Ordinary use

JIS B 2312: Steel Butt Welding Pipe Fittings.

JIS B 2313: Steel Plate Butt Welding Pipe Fittings

JIS B 2316: Steel Socket Welding Pipe Fittings |

Penetration Test

Applications Plumbing and Water Supply HVAC Systems Oil and Gas Industry Chemical Processing Power Plants Construction and Structural Applications Shipbuilding Food and Beverage Industry Pharmaceutical and Biotech Water Treatment:

|