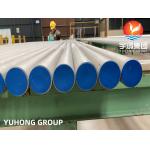

ASTM A312 TP310S Stainless Steel Seamless Pipe Pickled And PMI TestYuhong Special Steel has been engaged in seamless welded steel

pipes of austenitic stainless steel and nickel alloy steel

(Hastelloy, Monel, Inconel, Inconel) for more than 25 years, and

sells steel pipes every year. Over 80,000 tons. Our customers cover

more than 45 countries in Europe, Middle East, North and South

America, South Korea, Singapore, Australia, etc. Describe ASTM A312 310s is a long-term material for general corrosion

service and high temperature service. The composition of A312

Tp310s material includes carbon, manganese, silicon, phosphorus,

sulfur and chromium and nickel. This composition enables the

material to withstand strong oxidizing agents at high temperatures.

However, SA 312 Tp 310s has a lower carbon content than the

standard version, which increases the toughness of the pipe. In

contrast, the high temperature strength of 310s stainless steel

pipe products is reduced. Therefore, they are preferred in

applications that operate continuously at mild to high

temperatures. Due to the low carbon content, 310s stainless steel

welded pipe does not experience much intergranular corrosion.

Therefore, there is no localized corrosion of these pipes.

Therefore, applications that require extensive welding can use this

material grade. Excellent toughness and reduced corrosion make them

suitable for low temperature conditions as well. But the most

common application for Seamless 310 is general corrosion service. The 310s material also has a minimum yield strength of 205 MPa and

a minimum tensile strength of 525 MPa. This also allows the

material to be used under high pressure. The combination of all

these properties enables the material to be used in burners,

annealing caps, stills, combustion chambers, lead cans and radiant

tubes under these respective harsh conditions. SS 310s tubing is highly ductile and can be shaped as required.

Cold drawn tubing is easy to form, but SS 310s Erw tubing is

resistance welded and stronger. The different production mechanisms

used with this material grade have advantages. Our SS 310s round

tube is the most common, we offer other shapes such as SS 310s

square tube. If you have any questions, please contact us. 310S Pipe Specification Schedule| ASTM Specification Format | ASTM A312 / ASTM SA312 | | Dimensional ASTM / ASME Standard | ANSI/ASME B36.19M, ANSI/ASME B36.10M | | Shapes and Types we produce | Round, Honed, Rectangle, Hydraulic, Hex, Square | | Manufacturing Different Types | Welded, 100% X Ray Welded, Seamless, CDW, Fabricated, ERW | | Pipe End Forming | Beveled One End, Plain One End, Bevel small end, Treaded On End,

Treaded Both Ends, Bevel both ends, Plain Both Ends, Beveled end,

Bevel large end, Bevel one end | | TDC (Technical Delivery Conditions) | Polished, Annealed and Pickled, Cold Drawn, Bright Annealed | | Id and Od Finish Types | 2B, No.4, No.1, No.8 Mirror Finish or custom Finish as per customer

Requirements | | Pipe Wall Thickness Tolerance Chart | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS | | Other Value Added Facilities | Machining, Customer Tagging/ Marking, Export Documentation,

Grooving, Threading, Beveling, Non Destructive, Polishing,

Threading, Cutting, Color Coding, Ultrasonic Testing, Destructive,

MTR’s Available, Export Packaging, Material testing |

A312 TP310s Chemical Material Composition| ASTM A312 | Si | P | C | Mn | S | Cr | Mo | Ni | N | | 310s | min. | – | – | – | – | – | 24.0 | – | 19.0 | – | | max. | 1.50 | 0.045 | 0.25 | 2.0 | 0.030 | 26.0 | 22.0 | – |

|