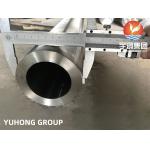

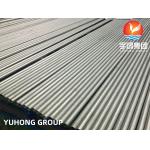

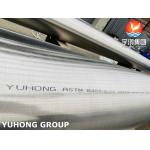

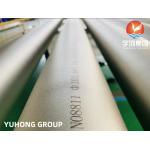

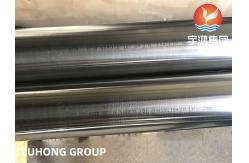

ASTM B729 UNS N08020 Alloy 20 2.4660 Nickel Alloy Steel Seamless

Pipe Annealed and Pickled. BE. PE. Alloy 20 Tube / Tubing / U-Bend Tube is made up of a nickel

chromium molybdenum alloy. It has high nickel content of 32-38%. It

is used mostly for applications that involve sulfuric acid. We are

a leading supplier and manufacturer of alloy 20 tubing. Alloy 20

Nickel Tubing has nickel, chromium, carbon, copper, molybdenum,

manganese, silicon, niobium and other elements in its chemical

composition. The copper content is mostly responsible for the

sulfuric acid resistance. There are seamless and welded tubes. The

UNS N08020 Seamless tube can range from 0.375 inches to 1 inches in

outer diameter where the welded tube can range from 0.125 inches to

1 inches. Also the wall thickness varies to seamless and welded

pipes. High Pressure Alloy 20 Nickel Tubing Supplier, Check Weight Chart

of UNS N08020 Seamless tube The welded tubes can have from 0.35 inches to 0.109 inches of wall

thickness while the seamless ones have only up to 0.065 inches. The

ASTM B729 alloy 20 tubes are of the welded pipe specification. With

annealing, the minimum tensile strength of the material is at

551MPa and the minimum yield strength is at 241MPa. The alloy 20

seamless tubing has a high melting point of 1443 degrees Celsius.

This allows the tubes to be used in high temperature applications.

The ASME SB729 Tube is meant for high temperature, high pressure

tubing. The copper content along with the high nickel content

allows the tubes to operate under high temperatures with high

acidic contents. Sometimes, the heat exchanger tubes of this grade

are called the Alloy 20 U Tube because they are manufactured in the

U shape. | Thickness | 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH

XXS, SCH XS | | Outer Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB | | Type | Seamless / ERW / Welded / Fabricated / CDW | | Form | Round Tubes, Square Tubes, Rectangular Tubes, Coiled Tubes, “U”

Shape, Pan Cake Coils, Hydraulic Tubes | | Length | Single Random, Double Random & Required Length | | End | Plain End, Beveled End, Treaded. |

Sizes of ASTM B729 Alloy 20 Tubes- Alloy 2.4660 ERW Tubes : 1/2″ NB – 24″ NB

- UNS N08020 Seamless Pipe : 1/2″ NB – 16″ NB

- Alloy UNS N08020 EFW Pipe : 6″ NB – 100″ NB

- Carpenter 20 Tubes : 1/8″NB TO 30″NB IN

Chemical Equation of 20 Alloy Welded Tube| Alloy 20 | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr | | 32 - 38 | 0.02 max | 2 - 3 | 1 - 2 | 0.7 max | Bal | 3 - 4 | 0.005 max | 0.02 max | 19 - 21 |

Mechanical Behaviour of ASME SB729 Alloy 20 Tubing| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation | | 8.1 g/cm3 | 1443 °C (2430 °F) | Psi - 35000 , MPa - 241 | Psi - 80000 , MPa - 551 | 30 % |

Equivalent of Carpenter 20 Electropolish Tube| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST | | Alloy 20 | N08020 | 2.4660 | Z2NCUD31-20AZ | NiCr20CuMo | - | - | - |

|