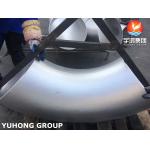

ASTM A182 F316L Threaded Forged Stainless Steel Elbow Pipe Fitting

|

ASTM A182 F316L Threaded Forged Stainless Steel Elbow Pipe Fitting

Yuhong is an industry-leading manufacturer, trader, supplier, and exporter in the ASTM A403 WP304 Socket Welded Pipe Fittings industry in China. Stainless steel A182 F316L contains higher chromium and lower carbon content, resulting in reduced susceptibility to intergranular corrosion. With a carbon content as low as 0.03%, this steel is highly resistant to chromium carbide precipitation caused by welding. It can withstand continuous exposure to temperatures of around 1500°F without significant fouling. This steel is suitable for various applications such as automotive headers, machine parts, screws, and food handling equipment. We offer a wide range of DIN 1.4404 stainless steel butt welded pipe fittings, including tees, reducers, crosses, short elbows, elbows, and end caps. SS UNS S30400 Butt Welded Pipe Elbow exhibits excellent forming and welding properties, as well as outstanding oxidation resistance. Our state-of-the-art infrastructure ensures that all our products are developed in accordance with international standards to achieve the highest quality. The ASTM A182 F316L specification covers forged or rolled alloy and stainless steel pipe flanges, forged fittings, valves, and parts for high-temperature service. After hot forging, specific temperature cooling and heat treatment processes should be carried out according to the requirements. The material must meet the chemical composition requirements for carbon, manganese, phosphorus, silicon, nickel, chromium, molybdenum, columbium, and titanium. Mechanical properties such as tensile strength, yield strength, elongation, and Brinell hardness of the specified grade should also be met. Average grain size testing is required for all grades of H and F 63. Socket weld connections involve inserting the pipe into a recessed area of a valve, fitting, or flange. Socket weld fittings are primarily used for small diameter pipes with a nominal diameter of NPS 2 or less, as compared to butt weld fittings. Fillet welds can be used to connect piping to valves, fittings, or other parts of the piping system. Socket welded joint construction is preferred due to its high leakage integrity and excellent structural strength. Socket weld fittings are widely used in various industrial processes, particularly for pipes carrying flammable, toxic, or expensive materials that must not leak, as well as for steam applications with pressures ranging from 300 to 600 PSI. They are designed to provide good flow characteristics, are produced according to ASTM standards, and manufactured to ASME B16.11 specifications. The B16.11 standard covers pressure-temperature ratings, dimensions, tolerances, markings, and material requirements for wrought carbon and alloy steels. These fittings are available in three pressure classes: 3000, 6000, and 9000. Socket weld fittings offer advantages such as easy alignment without the need for temporary spot welding, reduced risk of leaks compared to threaded fittings, and lower construction costs compared to butt-weld joints. However, it is important to ensure proper assembly and welding as radiography of fillet welds is not practical. ASTM A182 F316L Forged Socket Weld Fittings are a low carbon version of 316 stainless steel, offering excellent resistance to sensitization (grain boundary carbide precipitation). They are widely used for heavy welding parts (approximately 6mm or thicker). The price difference between 316 and 316L stainless steel is usually negligible. ASTM A182 F316L Forged Socket Weld Fittings, the standard molybdenum grade, rank second in importance among austenitic stainless steels, just after 304. Compared to 304, 316L exhibits superior overall corrosion resistance, especially resistance to pitting and crevice corrosion in chloride environments. These grades retain excellent toughness even at low temperatures due to their austenitic structure. Compared to chrome-nickel austenitic stainless steel, 316L stainless steel offers higher creep, rupture stress, and tensile strength at high temperatures. Yuhong provides a comprehensive range of ASTM A182 F316L forged socket welded pipe fittings, including elbows, tees, reducers, end caps, and joints. Chemical Composition of Grade WP316L

Mechanical Properties of SS 316L Forged Fittings

|

||||||||||||||||||||||||||||||

| Product Tags: Threaded Stainless Steel Elbow Pipe Forged Elbow Fitting |

|

ASTM A403 WPS31254 Duplex Stainless Steel 254SMO Fittings 90 Degree LR Elbow |

|

ASTM A815 UNS S32750 Super Duplex Stainless Steel Fittings 90 Degree LR Elbow |

|

ASTM B366 UNS N08810 Alloy 800H Buttweld Fittings 180 Degree Return Bend |

|

EN 10253-2 1.4541 Large Diameter Butt Weld Fitting 90 Deg Elbow |

|

ASTM A815 UNS S31803 Duplex 2205 90° LR Elbow ASME B16.9 Buttweld Pipe Fittings |

|

ASTM A815 Duplex Steel UNS S31803 Buttweld Pipe Fitting ASME B16.9 5D Elbow |