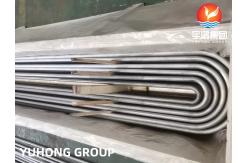

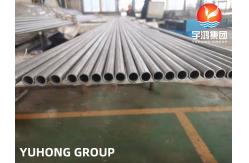

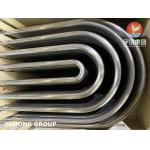

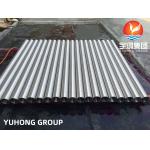

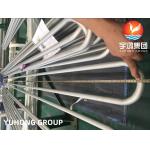

ASTM A213 / ASME SA213 TP444 Stainless Steel Seamless U Tube Heat Exchanger Tube

|

|

ASTM A213 / ASME SA213 TP444 Stainless Steel Seamless U Bend Tube For Heat Exchange

The advantage of TP444 Stainless Steel Tube: 1. Corrosion resistance: TP444 stainless steel is highly resistant to corrosion, making it suitable for applications where the tube will be exposed to aggressive environments, including acidic and chloride-rich conditions. 2. Heat resistance: TP444 exhibits good heat resistance, making it suitable for high-temperature applications such as heat exchangers and boilers. It can withstand elevated temperatures without significant distortion or degradation in performance. 3. U-bend capability: TP444 stainless steel is specifically designed and manufactured as U-bend tubes. They have excellent bending properties, allowing for easy fabrication of complex tube layouts, particularly in heat transfer systems. 4. Cost-effective option: TP444 stainless steel U-bend tubes can offer cost advantages compared to other stainless steel grades with similar performance characteristics. 5. Compatibility: TP444 stainless steel is compatible with various media, including water, steam, gases, and oils, making it versatile for use in different industrial settings.

ASTM A213 Grade TP444 Equivalents

Mechanical Property for ASTM A213 Seamless Steel Tube

Chemical Composition for ASTM A213 Seamless Steel Tube

Customer Specifications

Bending Radius: From 1.5*OD(Outside Diameter) To 1500mm When Ordering Tubes With Radius less or equal to 1.5*OD, It Is Necessary To Agree Precision Of Geometrics. Straight Tubes Maximum Length:(Before Bending): 35000 mm. Leg Length: Min 1 Meter, Max. 16500 mm (For Max R=1500mm) Note: Other Size Are Available Upon Agreement. Heat Treatment: Stress Relieved After U-Bending (Bending Area Plus 300MM For Each Leg). Hydrostatic Test After U Bending: Maximum Test Pressure 600 Bar, Soaking 10 Sec. With Dematerialized Water. Compressed Air Cleaning After Hydro-Test. Packaging: In Strong Transport-Worthy Pre-fumigated wooden boxes of corresponding dimensions for each tube Length, Radius, Diameter, According To PO requirements as well as wrapped In polyethylene films With soft plastic caps on both end of Tube.

Some of the quality tests carried out by us includes

Applications ASTM A213 TP444 U tubes are commonly used in heat exchanger and condenser applications where resistance to corrosion and high temperatures is required. Some of the common applications of these U-tubes include:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: U Bend Seamless Steel Tube Stainless Steel U Tube TP444 Stainless Steel U Bend Pipe A213 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

ASTM B163 Incoloy 800HT UNS N08811 Bright Surface Nickel Alloy Tube |

|

ASME SB163 UNS N04400 / Monel 400 Nickel Alloy Seamless Heat Exchanger Tube |

|

UNS NO6625/Din 2.4856/ASTM B444 Inconel 625 U Bend Tube Chemical Process Equipment NDT Available |

|

ASTM B622 / ASME SB622 Hastelloy C22 (UNS NO6022 ) Seamless Tube, Heat Exchanger /Boiler Application |