ASTM B622 Hastelloy C276 Nickel Alloy Seamless Tubes For Resistance

Of Oxidation

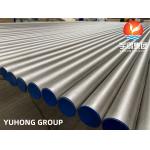

Hastelloy C276 Tubing is made of an excellent corrosion

resistant material with excellent resistance to pitting and creep.

Due to the composition, the material has all high mechanical

properties. Yuhong Group is a leading manufacturer and supplier of

Hastelloy C276 seamless pipes and others in different sizes, types

and shapes. The material consists of a mixture of nickel,

molybdenum, and chromium, known as a superalloy. The material is

resistant to most acids. As one of the leading suppliers of

Hastelloy C276 tubing, we manufacture tubing in diameters ranging

from 6mm to 50.8mm and wall thicknesses from 0.7mm to 3mm.

Hastelloy C276 tubing is available in seamless ERW, EFW, LSAW,

welded and fabricated types.

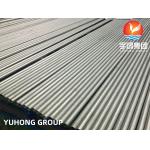

There are also different shapes such as round, square, rectangular

and hydraulic. These are used in various application types to meet

needs. Alloy C276 tubing is one of the most versatile material

grade tubing and can be used for almost any application

requirement. The material contains nickel, carbon, molybdenum,

manganese, silicon, iron, phosphorus, sulfur, cobalt and chromium.

This composition provides high strength to C276 Hastelloy tube. The

minimum yield strength is 355MPa and the minimum tensile strength

is 790MPa. Hastelloy UNS N10276 tubing also has a very high melting

point of 1370 degrees Celsius. Please feel free to contact us for

more information on products and prices.There are also different

shapes such as round, square, rectangular and hydraulic. These are

used in various application types to meet needs. Alloy C276 tubing

is one of the most versatile material grade tubing and can be used

for almost any application requirement. The material contains

nickel, carbon, molybdenum, manganese, silicon, iron, phosphorus,

sulfur, cobalt and chromium. This composition provides high

strength to C276 Hastelloy tube. The minimum yield strength is

355MPa and the minimum tensile strength is 790MPa. Hastelloy UNS

N10276 tubing also has a very high melting point of 1370 degrees

Celsius. Please feel free to contact us for more information on

products and prices.

1.Material:

UNS N06022, N10276, N06455, NN06635, N06200, N06030, N06035, N06002, N10003, N1001,

N10665, NN10675

ASTM B622 UNS N10276 Chemical Composition: | Hastelloy C276 | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr | | Balance | 0.010 max | 15.00 – 17.00 | 1.00 max | 0.08 max | 4.00 – 7.00 | 0.04 max | 0.03 max | 2.5 max | 14.50 – 16.50 |

ASTM B167 UNS N06601 Mechanical Properties:

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation | | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 52,000 , MPa – 355 | Psi – 1,15,000 , MPa – 790 | 40 % |

| ASTM B622 Alloy C276 Tubing Standards | ASTM B622/ ASME SB622, ASTM B626/ ASME SB626 |

|---|

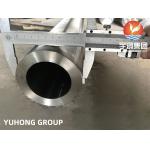

| ASTM B622 Alloy C276 Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

|---|

| ASTM B622 Alloy C276 Welded Tube Size | 6.35 mm OD To 152 mm OD |

|---|

| ASTM B626 Hastelloy C276 Tubing Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

|---|

| Inconel WERKSTOFF NR. 2.4819 Tube wall thickness | 0.020" –0.220", (special wall thicknesses available) |

|---|

| Inconel UNS N10276 Tubing Length | Single Random, Double Random, Standard & Cut length Tube |

|---|

| Inconel WERKSTOFF NR. 2.4819 Tubing Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed),

MF |

|---|

| Form | ‘U’ bent, Hollow, Hydraulic, LSAW, Boiler, Straight Tube, Tube

Coil, Round, Rectangular, Square Etc |

|---|

| Types of C276 Alloy Tubing | Seamless, ERW, EFW, Welded, Fabricated Tube / Tubing |

|---|

| C276 Alloy Tube End | Plain End, Beveled End, Treaded Tube |

|---|

| Marking | All ASTM B622 Hastelloy C276 Tubing are marked as follows:

Standard, Grade, OD, Thickness, Length, Heat No. (Or according to

the customer’s request.) |

|---|

| Application & uses of Hastelloy C276 Tube | Oil Tube, Gas Tube, Fluid Tube, Boiler Tube, Heat exchanger Tube, |

|---|

| Value Added Service | Draw & Expansion as per required Size & Length, Polish

(Electro & Commercial) Annealed & Pickled Bending,

Machining Etc. |

|---|

| Specialize in | ASTM B622 Hastelloy C276 Capillary Tube & Other Odd Size

Hastelloy NCF C276 Heat Exchanger & Condenser Tube |

|---|

| Test Certificate | Manufacturer Test Certificate

Laboratory Test Certificate from Govt. Approved Lab.

Under Third Party Inspection |

|---|

Equivalent Material Grade of Hastelloy C276 SMLS PIPE | STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST | | Hastelloy C276 | N10276 | 2.4819 | – | NiMo16Cr15W | NW 0276 | – | ХН65МВУ |

1.Hastelloy C276 Tubing Tests - Material certificate type EN 10204 Type 3.1

- Micro and MacroTest

- Positive Material Identification – PMI Testing

- Hardness Test

- Chemical Analysis – Spectro Analysis

- Intergranular Corrosion (IGC) Test

- Flaring Test

- Flattening Test

- Pitting Resistance Test

- Mechanical Testing Such as Tensile of Area

2.It is the responsibility of the purchaser to specify all

requirements that are necessary for the e and satisfactory

performance of material ordered under this specification. Examples

of such requirements include, but are not limited to, the

following:

1 Alloy—Name or UNS number,

2 ASTM designation, including year of issue,

3 Condition,

4 Finish,

5 Dimensions—Thickness, width, and length,

6 Quantity,

7 Optional Requirements:

7.1 Sheet and Strip—Whether to be furnished in coil, in

cut straight lengths, or in random straight lengths,

7.2 Strip—Whether to be furnished with commercial slit

edge, square edge, or round edge,

7.3 Plate—Whether to be furnished specially flattened; also how

plate is to be cut,

8 Certification—Certification is required, 9 Samples for Product (Check) Analysis—Whether

samples for product (check) analysis should be furnished,

10 Purchaser Inspection—If the purchaser wishes to witness tests or

inspection of material at the place of manufacture, the

purchase order must so state indicating which tests or inspections

are to be witnessed.

|