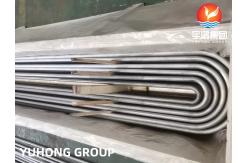

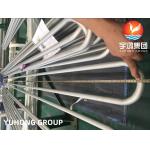

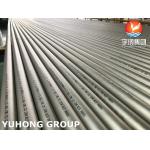

ASME SA213 TP444 Stainless Steel U Bend Heat Exchanger Tube

|

|

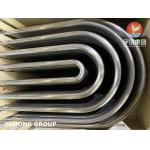

ASME SA213 TP444 Stainless Steel U Bend Heat Exchanger Tube Introduction The ASME SA213 TP444 is a ferritic stainless steel tube designed for high-temperature and corrosive environments, commonly used in heat exchangers, boilers, and superheaters. The U-bend design allows for thermal expansion and efficient heat transfer in shell-and-tube heat exchangers. Material Specifications Standard: ASME SA213 (Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes) Grade: TP444 (A ferritic stainless steel with improved corrosion resistance) UNS Designation: S44400 Chemical Composition

Mechanical Properties

Key Features & Advantages Excellent Corrosion Resistance – Resists pitting, crevice

corrosion, and stress corrosion cracking (SCC) in chloride

environments. Applications Shell-and-tube heat exchangers Condensers & evaporators Power plant boilers & superheaters Chemical processing equipment Oil & gas refineries Manufacturing & Testing Seamless construction (cold-drawn or hot-finished) U-bend forming (cold bending with precise radius) Non-destructive testing (NDT) (Eddy current, hydrostatic, ultrasonic) Heat treatment (Annealed for optimal corrosion resistance) Comparison with Other Grades

Conclusion The ASME SA213 TP444 U-bend tube is ideal for corrosive and high-temperature heat exchanger applications, offering superior chloride resistance compared to standard ferritic grades. Its U-bend design enhances thermal performance while minimizing mechanical stress. |

||||||||||||||||||||||||||||||||||||||||

| Product Tags: TP444 U Bend Tube ASTM B677 U Bend Tube U Bend ASTM A213 Tube |

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

ASTM B163 Incoloy 800HT UNS N08811 Bright Surface Nickel Alloy Tube |

|

ASME SB163 UNS N04400 / Monel 400 Nickel Alloy Seamless Heat Exchanger Tube |

|

UNS NO6625/Din 2.4856/ASTM B444 Inconel 625 U Bend Tube Chemical Process Equipment NDT Available |

|

ASTM B622 / ASME SB622 Hastelloy C22 (UNS NO6022 ) Seamless Tube, Heat Exchanger /Boiler Application |