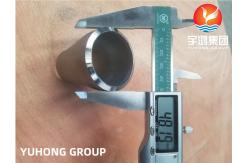

ASTM B366 / ASME SB366 UNS N06600 Inconel 600 Nickel Alloy Concentric Reducer

|

|

ASTM B366 / ASME SB366 UNS N06600 Nickel Alloy 600 Concentric Reducer

A concentric reducer is a type of fitting that is used to connect two pipes of different diameters in such a way that the center lines of the pipes are aligned. The reduction in diameter is gradual, forming a conical shape. This design ensures that the fluid flow remains smooth and uninterrupted, making it ideal for applications where there is a need for a consistent flow rate. On the other hand, an eccentric reducer is designed to connect two pipes of different diameters in such a way that the center lines of the pipes are not aligned. The reduction in diameter is also gradual, forming a conical shape, but the offset centerline creates an area of turbulence in the fluid flow. This design is useful in applications where there is a need to remove air or gases from the system, as the turbulence can help to separate these elements from the fluid.

Specification

Features and benefits of B366 Alloy 600 reducer:

ASME SB366 Inconel 600 Buttweld Fittings Equivalent Grades

Chemical Composition of Inconel 600 Alloy Pipe Fittings

Mechanical Properties of ASTM B366 / SB 366 Inconel 600 Pipe Fittings

The Alloy 600 Fittings possess superior strength and excellent

mechanical properties. They possess a minimum tensile strength of

655Mpa and a minimum yield strength of 310 Mpa. Inconel Tube

Fittings can be easily elongated by 40% and still possess excellent

workability. These fittings have a melting point of about 1413

degrees C and have a long service life. Applications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: astm b366 concentric reducer nickel alloy 600 concentric reducer asme sb366 flanged concentric reducer |

|

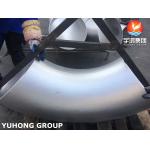

ASTM A403 WPS31254 Duplex Stainless Steel 254SMO Fittings 90 Degree LR Elbow |

|

ASTM A815 UNS S32750 Super Duplex Stainless Steel Fittings 90 Degree LR Elbow |

|

ASTM B366 UNS N08810 Alloy 800H Buttweld Fittings 180 Degree Return Bend |

|

EN 10253-2 1.4541 Large Diameter Butt Weld Fitting 90 Deg Elbow |

|

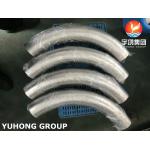

ASTM A815 UNS S31803 Duplex 2205 90° LR Elbow ASME B16.9 Buttweld Pipe Fittings |

|

ASTM A815 Duplex Steel UNS S31803 Buttweld Pipe Fitting ASME B16.9 5D Elbow |