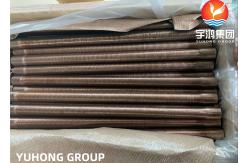

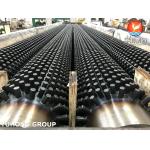

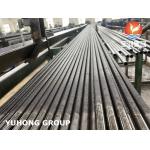

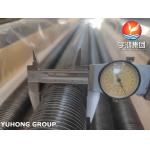

ASME SB111 C70600 Extruded Low Fin Tube | CuNi 90/10 Heat Exchanger Tubes

|

|

ASME SB111 C70600 Extruded Low Fin Tube | CuNi 90/10 Heat Exchanger Tubes Overview: C70600 is a copper-nickel alloy that is often used in the manufacturing of heat exchanger components such as tubes for oil coolers. Low fin tubes are tubes with enhanced surface area designed to improve heat transfer efficiency. When these tubes are used in oil coolers, they help increase the heat transfer rate between the oil and the surrounding medium. The key characteristics and advantages of C70600 low fin tubes used in oil coolers include: Excellent corrosion resistance: Copper-nickel alloys, including C70600, are known for their excellent corrosion resistance, especially in marine and industrial environments. Good thermal conductivity: Copper-nickel alloys are known for their high thermal conductivity, which allows for efficient heat transfer between the oil and the cooling medium. Resistance to biofouling: The alloy's resistance to biofouling makes it suitable for oil coolers used in marine applications where fouling can be a concern. High strength and durability: Copper-nickel alloys offer good mechanical strength and durability, ensuring a long service life for the oil cooler tubes. Easy to fabricate: C70600 is easy to fabricate into various forms, making it a popular choice for manufacturing heat exchanger components. Overall, C70600 low fin tubes are a reliable and efficient choice for oil cooler applications, offering excellent corrosion resistance, thermal conductivity, and durability to ensure efficient heat transfer in various industrial settings. Specification:

Chemical Composition:

Application: The application of C70600 low fin tubes can be found in heat exchangers, especially in marine environments where corrosion resistance is crucial. These tubes are used in various industries like seawater desalination plants, offshore oil platforms, shipbuilding, and power plants. The increased surface area provided by the fins helps enhance heat transfer efficiency, making C70600 low fin tubes suitable for applications where high heat transfer rates are required. |

|||||||||||||||||||||||||||||||||||||||||||

| Product Tags: astm b111 heat exchanger fin tube cuni 90/10 low fin tube c70600 low fin tube |

|

Studded Tube , ASTM A213 T9 / ASME SA213 T11 with 11Cr (SS 409) Studded Fin Tube ,Steam Reforming Furnace |

|

ASME SA179 , ASTM A179 Carbon Steel Low Finned Tube, for Air Cooler, cooling tower application |

|

Welded Helical Serrated Fin Tubes HFW Fin Tube For Per Heating Application |

|

ASME SA210 Gr.A1 Seamless Tube with Aluminum Al1060 Embedded G type Fin tube |

|

ASTM A179/ ASME SA179 Carbon Steel Seamless Tube with Aluminum 1060, Air Cooler, Extruded Fin Tube ,Embedded G Fin Tube |

|

ASTM A179 Carbon Steel Seamless Tube with Aluminum ASTM B221 6063 (1060), Extruded Fin Tube |