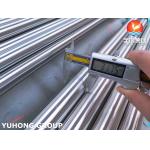

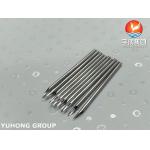

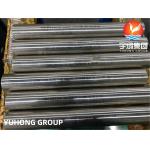

ss nail wire non-magnetic stainless steel nail wire

in with suitable tensile strength

Product DescriptionOver the years of experience in the industry, we have been able to

provide the customers with an astounding assortment of Stainless Steel Nail Wire. These wires are designed with utmost perfection in compliance

with the international quality standards to attain highest

benchmarks of quality. Available in different specifications and

sizes, these wires are available at industry leading prices.

Features:

Super-fine stranded wire Flame tested Maximum flexibility

Specifications:- Size : 0.8mm to 6.0mm (0.031 to 0.236)

- Grades : 304, 316, 304HC, 302HQ

- Finish : Matt, Soap Coated

- Temper : Soft, ¼ Hard

- Packing : Coils 200-500 kgs, 2-3 Coils on carriers.

Mechanical properties

DIAMETER(MM) | TENSILE STRENGTH(MPA) | ELONGATION(%) |

SOFT-ANNEALED |

SEMI-HARD |

HARD | FOR SOFT-ANNEALED WIRE ONLY | | 0.20~0.30 | 640~980 | _ | _ | ≥20 | | 0.30~0.60 | 590~930 | _ | _ | ≥20 | | 0.60~1.00 | 540~880 | 830~1180 | 1180~1520 | ≥25 | | 1.00~3.00 | 490~830 | 780~1130 | 1130~1470 | ≥25 | | 3.00~6.00 | 490~830 | 730~1080 | 1080~1420 | ≥30 | | 6.00~14.00 | 490~790 | 730~1030 | _ | ≥30 |

Physical Properties

| Diameter Tolerance & Oval Tolerance | Mechanical Properties | | (mm)Dia. | (mm)Dia.Tolerance | Oval.Tolerance | | 0.030-0.050 | ±0.003 | ≤0.003 | | 0.050-0.080 | ±0.004 | ≤0.004 | | 0.080-0.10 | ±0.005 | ≤0.005 | | 0.10-0.16 | ±0.007 | ≤0.007 | | 0.16-0.28 | ±0.010 | ≤0.010 | | 0.28-0.50 | ±0.013 | ≤0.013 | | 0.50-0.90 | ±0.015 | ≤0.015 | | 0.90-1.60 | ±0.02 | ≤0.02 | | 1.60-2.80 | ±0.03 | ≤0.03 | | 2.80-5.00 | ±0.04 | ≤0.04 | | 5.00-9.00 | ±0.05 | ≤0.05 | | 9.00-12.00 | ±0.06 | ≤0.06 | | 12.00-14.00 | ±0.07 | ≤0.07 |

| | Type | (mm)Dia | (N/mm2)Tensilestrength | (%)Elongation | | SUS304.SUS304L | 0.02-0.05 | 880-1130 | ≥10 | | SUS316.SUS316L | 0.02-0.05 | 650-900 | ≥8 | SUS304.SUS304L

SUS309S

SUS310S

SUS316.SUS316L

SUS321 | 0.05-0.16 | 650-900 | ≥20 | | 0.16-0.50 | 610-860 | | 0.50-1.60 | 570-820 | ≥30 | | 1.60-5.00 | 520-770 | | 5.00-14.00 | 500-750 | | SUS304J3 | 0.05-0.16 | 620-870 | ≥20 | | 0.16-0.50 | 580-830 | | 0.50-1.60 | 540-790 | ≥30 | | 1.60-5.00 | 500-750 | | 5.00-14.00 | 490-740 |

|

Chemical Composition

| AISI Grade | Chemical Composition(%) | | | C | Si | Mn | P | S | Ni | Cr | Mo | | 304 | =<0.08 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 8.00~10.50 | 18.00~20.00 | - | | 304H | >0.08 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 8.00~10.50 | 18.00~20.00 | - | | 304L | =<0.030 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 9.00~13.50 | 18.00~20.00 | - | | 316 | =<0.045 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 10.00~14.00 | 10.00~18.00 | 2.00~3.00 | | 316L | =<0.030 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 12.00~15.00 | 16.00~18.00 | 2.00~3.00 | | 430 | =<0.12 | =<0.75 | =<1.00 | =<0.040 | =<0.030 | =<0.60 | 16.00~18.00 | - | | 430A | =<0.06 | =<0.50 | =<0.50 | =<0.030 | =<0.50 | =<0.25 | 14.00~17.00 | - |

How to Enquiry Topone Stainless Steel Forming Wire in

Efficiency

In order to quote you asap with right material in good price,we

need you quote us with 10 details below .If you only know parts of

them or only the wire application, you can talk with us online for

help:

| 1 | Your wire application | Required | | 2 | Wire Grade | Required | | 7 | Wire Shape and Size | Required | | 3 | Wire Surface Finish | Required | | 4 | Wire Tensile Strength Level | Required | | 5 | Quantity/Weight | Required | | 6 | Wire Manufacturing Standards | Required | | 8 | Wire Tolerence | Prefered | | 9 | Delivery Time | Prefered | | 10 | Wire Package | Optional |

|

|