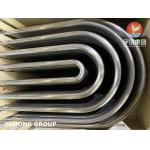

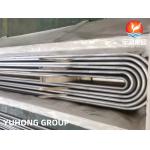

B111 C68700 Aluminium Brass o61 Annealed U Bend Tube Copper Alloy Cold Drawn

|

B111 C68700 Aluminium Brass o61 Annealed U Bend Tube Copper Alloy Cold Drawn

Overview

B111 C68700 Aluminum Brass Seamless Tube refers to a specific grade of seamless tube made from C68700 Aluminum Brass that meets the ASTM B111 standard. The ASTM B111 standard outlines the requirements for Seamless Copper and Copper-Alloy Condenser and Heat Exchange Tubes, including C68700 (Aluminum Brass), which is commonly used for heat exchangers, condensers, and similar applications where high corrosion resistance and thermal conductivity are crucial. B111 C68700 Aluminum Brass Seamless Tube is a high-performance material that combines the corrosion resistance of aluminum brass with the mechanical benefits of a seamless construction. Adhering to ASTM B111 specifications, it is ideal for applications that require reliable, durable, and corrosion-resistant tubes, such as heat exchangers, condensers, marine systems, and HVAC equipment. The seamless nature of these tubes provides superior strength, resistance to internal pressure, and smoother internal surfaces, making them particularly suited for high-stress and high-performance environments.

ASTM B111/B111M Standard Specification for Copper and Copper-Alloy Seamless Tubes

Applications:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: astm b111 u bend tube c68700 u bend tube b111m u bend tube | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

ASME SA213 TP347 TP347H Stainless Steel U Bend Tube ET/HT for Heat Exchanger Tube |

|

ASTM A213 TP304L Austenitic Stainless Steel Seamless U Bend Tube |

|

A213 TP304 Stainless Steel Bright Annealed U Bend Tube Seamless |

|

Boiler U Tube ASTM A213 TP304 / 304L SS Seamless U Bend Tube |