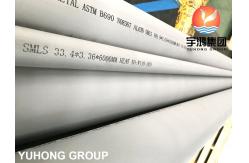

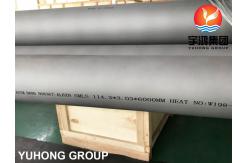

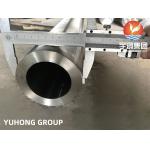

B690 ALLOY8367 / AL-6XN / DIN1.4501 NICKEL ALLOY STEEL SEAMLESS PIPE

|

|

B690 ALLOY8367 / AL-6XN / DIN1.4501 NICKEL ALLOY STEEL SEAMLESS PIPE

Overview

AL6XN is a superaustenitic stainless steel with outstanding resistance to chloride pitting, crevice corrosion and stress corrosion cracking. AL6XN is a 6 moly alloy that was developed for and is used in highly aggressive environments. It has high nickel (24%), molybdenum (6.3%), nitrogen and chromium contents that give it excellent resistance to chloride stress corrosion cracking, chloride pitting, and exceptional general corrosion resistance. AL6XN is primarily used for its improved pitting and crevice corrosion resistance in chlorides. It is a formable and weldable stainless steel.Because of its nitrogen content, AL6XN has greater tensile strength than common austentitic stainlesses, while retaining high ductility and impact strength.

Alloy AL6XN is a low carbon, high purity, nitrogen-bearing"super-austenitic"nickel-molybdenum alloy with excellent resistance to chloride pitting and crevice corrosion. Alloy AL6XN's high strength and corrosion resistance makes it a better choice than the conventional duplex stainless steels and a cost effective alternative to more expensive nickel-base alloys where excellent formability, weldability, strength and corrosion resistance are essential.

The high nickel and molybdenum contents provide improved resistance to chloride stress-corrosion cracking. Copper (Cu) has been intentionally kept to a residual level for improved performance in seawater40. The high alloy composition of the AL-6XN alloy resists crevice corrosion and pitting in oxidizing chloride solutions to a degree previously achieved only by nickel-base alloys and titanium.

Specification ASTM B690-18 Standard Specification for Iron-Nickel-Chromium-Molybdenum Alloy (UNS N08367) Seamless Pipe and Tube.

Which include:

Chemical Composition

Mechanical Properties

Corrosion Resistance

Chromium, molybdenum, nickel and nitrogen all contribute to overall resistance to corrosion by various media. Chromium is the principal agent for conferring corrosion resistance in neutral or oxidizing environments. Chromium, molybdenum and nitrogen increase resistance to pitting corrosion. Nickel imparts the austenitic structure. Nickel and molybdenum both provide increased resistance to chloride stress corrosion cracking in reducing environments.

Applications:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: din1.4501 nickel alloy pipe astm b690 nickel alloy pipe 8367 nickel alloy tube |

|

Bright Surface ASTM B729 NO8020 Nickel Alloy Pipes for High-Pressure and High-Temperature Environments |

|

ASTM B622 UNS N10276 2.4819 Hastelloy C276 Seamless Nickel Alloy Pipe Tube |

|

ASME SB622 Hastelloy C276 Nickel Alloy Seamless Tube for Aerospace industry |

|

ASTM B407 INCOLOY 800HT / UNS NO8811 NICKEL ALLOY SEAMLESS PIPE |

|

Nickel Alloy Seamless Pipe ASTM B407/ B163 UNS NO8800 UNS NO8810 UNS NO8811 |

|

ASTM B407 UNS N08811( Incoloy 800HT)/ DIN 1.4958 Nickel Alloy Seamless Pipe Annealed&Pickeled |