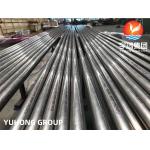

ASTM A335 / ASME SA335 P9 SEAMLESS ALLOY STEEL SMLS PIPE

A335/SA335 P9 is a seamless ferritic alloy-steel pipe used for

high-temperature applications. These pipes are versatile and can be

used to transmit water, oil and natural gas.

Key to the composition of chrome moly alloy P9 is the addition of

chromium and molybdenum. Chromium, or chrome, improves

high-temperature strength, increases oxidation resistance and

raises the tensile, yield and hardness at room temperatures.

Molybdenum increases the strength, elastic limit, resistance to

wear, impact qualities and hardenability. It increases the

resistance to softening, restrains grain growth and makes chromium

steel less susceptible to embrittlement. Moly is also the most

effective additive for increasing high temperature creep strength,

or creep resistance. It also enhances the corrosion resistance of

steel and inhibits pitting.

Both these elements are known to improve the pipe’s resistance to

wear, its impact qualities, hardenability, as well as its elastic

limit. They also cause an increase in its mechanical properties

like: the prevention of grain growth, reduced brittleness, the

increase the creep strength at high temperatures and has excellent

resistance to softening.

The chromium content in the a335 p9 pipe makes it highly resistant

to corrosion. Therefore, the a335 p9, has excellent resistance to

oxidation at elevated temperature. Besides chromium, astm a335 p9

alloy steel pipes that are externally coated with either Black oil

paint or anti-corrosion oil show good resistance to corrosion. It

could also be galvanized with zinc. Galvanization with zinc

increases its resistance to atmospheric corrosion.

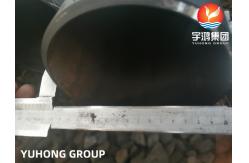

A335 P9 Pipes may be manufactured by forming them either through

hot finishing or cold drawing. After forming, the pipes have to be

finished with heat treatment that includes Full or Isothermal

Annealing, Normalizing and Tempering. There are four types of sa335

grade p9 pipes that are manufactured - Welded, Fabricated, Seamless

and ERW. The pipes are available in threaded ends, plain ends or bevel end.

And both the ends of these pipes are protected by plastic caps. The

asme sa335 grade p9 pipes and tubes are manufactured in several

forms like – rectangle, coiled, round, square, hydraulics, U-shaped

and pancake coils.

ALLOY PIPE CROSS REFERENCE TABLE ASTM vs. EN GRADES

| Chrome Moly Pipes: Werkstoff vs EN vs ASTM |

|---|

| Werkstoff /DIN | EN | ASTM |

|---|

| 1.5415 | 16Mo3 | A335 Grade P1 |

| 1.7335 | 13CrMo4-5 | A335 Grade P11, P12 |

| 1.7380 | 10CrMo9-10 | A335 Grade P22 |

| 1.7362 | X11CrMo5 | A335 Grade P5 |

| | | A335 Grade P9 |

| 1.4903 | X10CrMoVNb9-1 | A335 Grade P91 |

Chemical composition(%):

| Grade | C | Mn | P≤ | S≤ | Si | Cr | Mo |

| P11 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

| P22 | 0.05-0.16 | 0.30-0.60 | 0.025 | 0.025 | ≤0.50 | 1.90-2.60 | 0.87-1.13 |

| P5 | ≤0.15 | 0.30-0.60 | 0.025 | 0.025 | ≤0.50 | 4.00-6.00 | 0.45-0.65 |

| P9 | ≤0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.25-1.00 | 8.00-10.00 | 0.90-1.10 |

| P91 | 0.08-0.12 | 0.30-0.60 | 0.020/0.010 | 0.020/0.010 | 0.02-0.50 | 8.00-9.50 | 0.85-1.05 |

| P92 | 0.07-0.13 | 0.30-0.60 | 0.020/0.010 | 0.020/0.010 | ≤0.50 | 8.50-9.50 | 0.30-0.60 |

Mechanical properties:

| Grade | Tensile strength | Yield strength | Elongation |

| P11, P22, P5, P9 | ≥415 | ≥205 | ≥30/20 |

| P91 | ≥585 | ≥415 | ≥20 |

| P92 | ≥620 | ≥440 | ≥20 |

Application:

A335/SA335 Seamless P9 pipe is often used in the oil and natural

gas industry due to its high strength. P9’s great performance

properties make it suitable for energy-related applications. P5 is

suitable for:

- Refinery

- Machine building

- Oil and gas

- Power generation

- Petrochemicals

- Gas processing

- Fertilizer

- Sugar