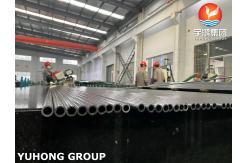

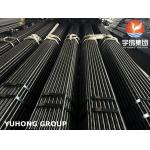

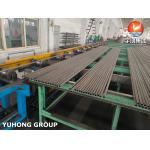

EN10305-1 E235+N NBK SEAMLESS PRECISION TUBE FOR AUTO APPLICATION

|

Detailed Product Description

|

EN10305-1 E235+N NBK SEAMLESS PRECISION TUBE FOR AUTO APPLICATION

Delivery Status: NBK (+N) BKW (+LC) GBK (+A) BKS (+SR) BK (+C) OD x WT = 4~120 x 0.5~15mm DIN2391 St52.4+N Phosphated Hydraulic Tube

Description: Precision steel tube Grade: St 30 Si / St 30 Al / St 35 / St37 / St37.4 / St45 / St 52 / St52.4 / E215 / E235 / E355 Precision in size,Bright for the surface, high ability of

mechanical performance Standard: DIN 2391, EN10305-1, EN10305-4, BS 6323, ISO 8535 DIN2391 Precision steel pipe STEEL GRADE: ST30Si, ST30Al, ST35, ST37, ST37.4, ST45, ST52,

ST52.4, etc Size:(mm) Out Dimensions: 6 mm ~ 350 mm Wall Thickness: 0.8 mm ~30mm Length: Fixed(6m,9m,12,24m) or normal length(5-12m)

Final supply conditions: Cold finished(hard)BK Tubes do not undergo heat treatment following the final cold

forming and, thus, have a rather high resistance to deformation. Cold finished(soft)BKW The final heat treatment is followed by cold drawing involving

limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending,

expanding) Cold finished and stress-relieved BKS Heat treatment is applied following the last cold forming process.

Subject to appropriate processing conditions, the increase in the residual stresses involved enables

both forming and machining to a certain degree. Annealed GBK The last cold forming process is followed by annealing

in a controlled atmosphere.

Normalized NBK The last cold forming process is followed by annealing above the

upper transformation point in a controlled atmosphere.

Chemical Composition:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: DIN2391 Seamless Boiler Tube Heat Exchanger Seamless Precision Tube Galvanized Seamless Precision Tube | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

|

EN 10216-2 13CrMo4-5 1.7335 Seamless Boiler Tubes For Performance In High-Temperature |

|

EN10305 E235+N 1.0308 Carbon Steel Seamless Boiler Tube |

|

SA179 Carbon Steel Seamless Tube For Reactor Effluent Air Cooler REAC |

|

EN10216-2 TC2 P235GH 1.0345 Carbon Steel Seamless Boiler Tube |

|

ASTM A192 / ASME SA192 Carbon Steel Seamless Boiler Tube |

|

ASTM A179 / SAME SA179 Carbon Steel Seamless Tube Heat Exchange Tube |

Email to this supplier