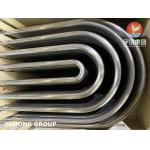

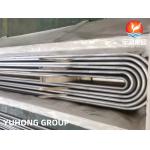

Heat Exchanger Tube SA213 / SA213-2018 TP321 Seamless Boiler Tubes 100% ET & HT

|

|

Heat Exchanger Tube SA213 / SA213-2018 TP321 Seamless Boiler Tubes 100% ET & HT

YUHONG GROUP deal with Austenitic Stainless Steel, Nickel Alloy Steel(Hastelloy , Monel, Inconel, Incoloy ) seamless and welded pipe and tube already more than 25 years, every year sell more than 80000 tons of steel pipe and tube. Our client already cover more than 45 countries, Like Italy, UK, Gernmany, USA, Canada, Chile, Colombia, Saudi Arabia, Korea, Singapore, Austrial, Poland, France , ....And our group branch company and factory have been already approved by :ABS, DNV, GL, BV, PED 97/23/EC, AD2000-WO, GOST9941-81, CCS, TS, CNNC, ISO9001-2008, ISO 14001-2004.

Specification: ASME SA213/A213: Standard Specification for Seamless Ferritic and Austenitic Alloy- Steel Boiler, Superheater and Stainless Steel Heat Exchanger Tubes.

ASTM A249 / A249M:Standard Specification for Welded Austenitic Steel Boiler, Superheater

Heat-Exchanger, and Condenser Tubes.

Other Standard:DIN 17456 , DIN 17458, EN10216-5, GOST 9940-81, GOST 9941-81, JIS-G3463,...

Material Grade:

Size Range:

Final Finishing Solution Annealed & Pickled/Bright Annealed.

Type of Tubes: U-bend & Straight.

Some of the quality tests carried out by us includes:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: heat exchanger pipe seamless stainless steel tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

ASME SA213 TP347 TP347H Stainless Steel U Bend Tube ET/HT for Heat Exchanger Tube |

|

ASTM A213 TP304L Austenitic Stainless Steel Seamless U Bend Tube |

|

A213 TP304 Stainless Steel Bright Annealed U Bend Tube Seamless |

|

Boiler U Tube ASTM A213 TP304 / 304L SS Seamless U Bend Tube |