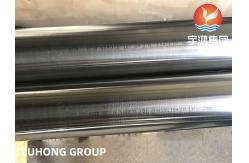

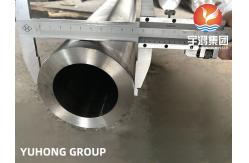

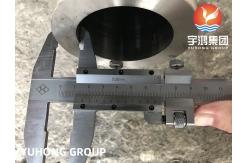

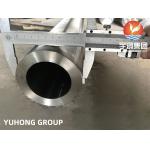

Nickle Alloy Pipe ASTM B729 Alloy20 ,N08020, 2.4660 Hastelloy Pipe

|

|

Nickle Alloy Pipe ASTM B729 Alloy20 ,N08020, 2.4660 Hastelloy Pipe

Alloy 20 (also known as Carpenter 20 or UNS N08020) is a nickel-iron-chromium austenitic alloy developed primarily for corrosion resistance in environments containing sulfuric acid. It also contains copper and molybdenum, which enhance its overall corrosion resistance. Alloy 20 was designed specifically to withstand sulfuric acid. Its nickel, chromium, molybdenum and copper levels all provide excellent general corrosion resistance. Restricted carbon plus columbium stabilization permits welded fabrications to be used in corrosive environments, normally without post-weld heat treatment. At 33% nickel, Alloy 20 has practical immunity to chloride stress corrosion cracking. This alloy is often chosen to solve SCC problems, which may occur with 316L stainless. Advantages of Alloy 20:

Common Applications:

ALLOY20 (NO8020 / 2.4660) Chemical Component:

Physical PropertiesDensity: 0.278 lb/in3 annealed Mechanical Properties

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: heat exchanger pipe heat recovery pipe |

|

Bright Surface ASTM B729 NO8020 Nickel Alloy Pipes for High-Pressure and High-Temperature Environments |

|

ASTM B622 UNS N10276 2.4819 Hastelloy C276 Seamless Nickel Alloy Pipe Tube |

|

ASME SB622 Hastelloy C276 Nickel Alloy Seamless Tube for Aerospace industry |

|

ASTM B407 INCOLOY 800HT / UNS NO8811 NICKEL ALLOY SEAMLESS PIPE |

|

Nickel Alloy Seamless Pipe ASTM B407/ B163 UNS NO8800 UNS NO8810 UNS NO8811 |

|

ASTM B407 UNS N08811( Incoloy 800HT)/ DIN 1.4958 Nickel Alloy Seamless Pipe Annealed&Pickeled |