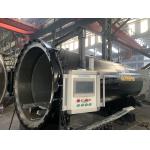

Composite autoclave for aircraft materials

Composite High Pressure Vessel for Aircraft Materials

A composite high pressure vessel is a crucial component used in

aircraft materials. This vessel is designed to withstand high

pressure conditions and is constructed using composite materials.

The use of composites in aircraft materials is gaining popularity

due to their exceptional strength-to-weight ratio and resistance to

corrosion. These materials are typically composed of a combination

of fibers, such as carbon or glass, embedded in a matrix material,

such as epoxy resin.

The composite high pressure vessel is specifically designed to

store and transport pressurized gases or liquids in aircraft. It is

capable of withstanding high pressures while maintaining its

structural integrity. This is essential for the safe operation of

the aircraft and ensures the containment of the pressurized

substances.

The construction of the vessel involves several layers of composite

materials, which are carefully laid up and cured to form a strong

and durable structure. These layers are strategically arranged to

provide optimal strength and stiffness, while also considering

weight reduction.

The composite high pressure vessel offers several advantages over

traditional metallic vessels. Firstly, it is significantly lighter,

which contributes to fuel efficiency and overall aircraft

performance. Additionally, composites have a higher resistance to

fatigue and corrosion, resulting in a longer lifespan for the

vessel.

Moreover, the use of composite materials allows for greater design

flexibility, enabling the vessel to be customized according to

specific aircraft requirements. This flexibility also allows for

the integration of additional features, such as sensors or

insulation, further enhancing the functionality of the vessel.

In conclusion, the composite high pressure vessel plays a crucial

role in aircraft materials. Its use of composite materials provides

numerous advantages, including weight reduction, increased

durability, and design flexibility. By utilizing this advanced

technology, aircraft manufacturers can enhance the performance,

safety, and efficiency of their aircraft.