What is the structure of composite material composite autoclave

|

|

What is the structure of composite material composite autoclave

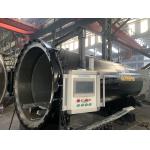

The structure of a composite high-pressure vessel includes multiple layers of different materials bonded together. The innermost layer is typically made of a high-strength material such as carbon fiber reinforced polymer (CFRP) or glass fiber reinforced polymer (GFRP) to provide the necessary strength and resistance to high pressure. This inner layer is then surrounded by a layer of resin or matrix material, which helps to distribute the load and provide additional strength.

On top of the matrix layer, there may be additional layers of reinforcement materials such as woven fabrics or unidirectional fibers, which further enhance the structural integrity of the vessel. These reinforcement layers can be made of different materials depending on the specific requirements of the application, including carbon fibers, glass fibers, aramid fibers, or other high-strength fibers.

Finally, the outermost layer of the composite high-pressure vessel is typically a protective coating or barrier mate.

|

| Product Tags: Hot oil boiler oil fired boiler |

|

Sharp tool for improving production efficiency: Analysis of the advantages of Composite Autoclave cans |

|

Analysis of the working principle and application field of the Composite Autoclave |

|

The important role and application cases of Composite Autoclave in metal processing |

|

Development Trends and Future Prospects of Composite Autoclave Technology |

|

Precautions and safety assessment for the operation of Composite Autoclave |

|

Comparative analysis of Composite Autoclave and other heat treatment equipment |