Composite Autoclave forming process

|

|

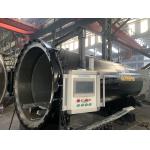

Composite Autoclave forming process

Composite High-pressure Vessel Molding Process The composite high-pressure vessel molding process involves several steps. Firstly, a mold is prepared, which is typically made of steel or aluminum. The mold is carefully designed to have the desired shape and dimensions of the high-pressure vessel.

Next, the composite materials are prepared. This usually involves combining different types of fibers, such as carbon or glass fibers, with a matrix material, such as epoxy resin. The fibers are typically arranged in a specific pattern to provide the desired strength and stiffness to the final product. Once the composite materials are prepared, they are placed into the mold. This can be done by hand or using automated machinery, depending on the size and complexity of the vessel. The materials are carefully layered and compacted to ensure proper distribution and consolidation.

After the materials are placed in the mold, the mold is closed and sealed. The vessel is then subjected to high pressure and temperature conditions. This is typically achieved using an autoclave or a pressurized oven. The high pressure and temperature help to cure the resin and bond the fibers together, resulting in a strong and durable composite structure.

After the curing process is complete, the mold is opened and the high-pressure vessel is removed. Any excess material is trimmed and the vessel is inspected for quality and dimensional accuracy. Additional finishing processes, such as sanding or painting, may be performed to achieve the desired surface finish.

In conclusion, the composite high-pressure vessel molding process involves preparing the mold, combining and compacting the composite materials, subjecting the vessel to high pressure and temperature, and finishing the final product. This process allows for the production of high-quality and high-performance composite high-pressure vessels.

|

| Product Tags: Hot oil boiler fuel oil boiler efficiency |

|

Sharp tool for improving production efficiency: Analysis of the advantages of Composite Autoclave cans |

|

Analysis of the working principle and application field of the Composite Autoclave |

|

The important role and application cases of Composite Autoclave in metal processing |

|

Development Trends and Future Prospects of Composite Autoclave Technology |

|

Precautions and safety assessment for the operation of Composite Autoclave |

|

Comparative analysis of Composite Autoclave and other heat treatment equipment |