Large Air Cooling Cnc Machining Aluminium Heatsink Extrusion

|

|

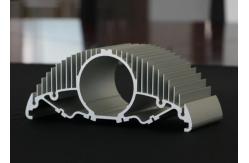

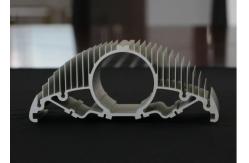

Large Air Cooling Aluminum Heat Sink Extrusion Profiles With Cnc

Machining

Technology Supports 1. Engineering Design. 2. Quality Standard: China GB, according to the Drawing and the Customer's Details.

Tag : LED Aluminum Heat Sinkextruded aluminum heat sink |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: cnc machining aluminium heatsink extrusion 6063 aluminium heatsink extrusion 6005 heat sink aluminium extrusion |

|

Customized Silvery Anodized Radiator Aluminium Extrusion Heat Sink Profiles |

|

Round High Power Aluminum Heatsink Extrusion Profiles Sliver Matt Finishing |

|

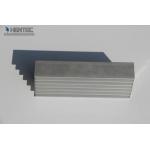

Aluminum Extrusion Profiles Cutting Drilling CNC Machining Anodized |

|

6063 - T5 Aluminum Heatsink Extrusion Profiles Powder Spray Coated |

|

T66 Aluminum Heatsink Extrusion Profiles Radiator Electrophoretic Coated |

|

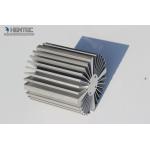

High Power LED Aluminum Heatsink Extrusion Profiles Different Surface Treatment |