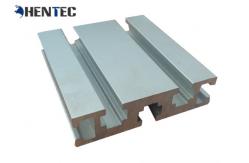

Assembly Line Industrial Aluminium Profile , Aluminum Extrusion Profiles 6063- T5 / T6

|

|

Assembly Line Industrial Aluminium Profile , Aluminum Extrusion Profiles 6063- T5 / T6

Product Specification

Applications:

Mainly used for industrial production , such as automation equipment , enclosure of the skeleton and the companies according to their own customized mold machinery and equipment , such as assembly line conveyor , hoist, dispenser, testing equipment, shelves , etc., electronic machinery industries and clean room with a gain majority.

Specifications:

1. Primary Technical Data

1)Chemical composition

2)Mechanical property

Competitive Advantage:

1) Engineering design and support. 2) Aluminum profiles deeply processing:cutting,punching,drilling,milling,and fabricating. 3) High Quality system, strictly inspection during production and whole inspection before package. 4) Good performance, product warranty for 15 years.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: aluminum extrusion profiles aluminium door frame | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Customeized Aluminum Trailer Industrial Aluminium Profile with Powder Painted |

|

Cars , Trains Machinery Industrial Black , Golden Aluminium Profile PVDF Coating |

|

T4 Anodized Industrial Aluminum Profile AAMA AS Milling Drilling |

|

T Slots V Slots 6061 Industrial Aluminum Profiles |

|

CA T Slot 6063 Custom Aluminum Extrusions For Assembly Line |

|

T5 OEM 6063 Alloy Aluminium Construction Profiles |