SJSZ 65X132 PVC Window Profile Extrusion Line Twin Screw Plastic Making Machine

|

|

PVC Window and Door Profile Extrusion Line , SJSZ65X132 PVC Plastic Profile Making Machine

Quick details: 1.This machine is mainly used to produce PVC window & door profiles, PVC trunking profiles, PVC ceiling profiles, PVC panel, PVC board and so on. This PVC profile extrusion line adopts advanced design concept to ensure the efficient extrusion of PVC material, combined with the unique concept of plasticization screw design to ensure uniformity of plastic extrusion, high capacity production. 2.It is designed for producing various size of plastic composite products,such as PVC WPC profiles,WPC board,WPC decorate panel.Our WPC machine has features of low consumption,low noise,stable running..

Description of plastic profile production line:

a. Conical twin screw extruder: b. Extrusion Mould: c. Spraying and cooling table: d. Haul off machine: e. Cutting machine: 6. Stacking:

Technical Parameter:

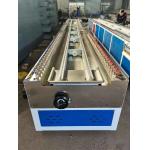

Machine dispaly:

|

|||||||||||||||||||||||||

| Product Tags: Automatic PVC Window Profile Extrusion Line SJSZ PVC Window Profile Extrusion Line Twin Screw PVC Profile Extrusion Line |

|

Customized Plastic Profile Extrusion Line Advanced Processing Technology Qingdao Port |

|

Customized Size Design Plastic Extruder Machine Low Noise |

|

PVC Profile Production Line, UPVC WPC Window Door Profile Extrusion Machine , PVC Extruder |

|

Manufacturing Process Of UPVC Profile , PVC Windows Profile Production Line , PVC Profile Extrusion Line |

|

PVC WPC Profile Machine WPC PVC Window Door Plastic Profile Production Line With Twin Screw Extruder |

|

PVC Window and Door Profile Extrusion Line , WPC Door and Frames Profile Making Machine, Plastic Coner Extrusion |