200mm PVC Double Wall Corrugated Pipe Extruder Fully Automatic

|

|

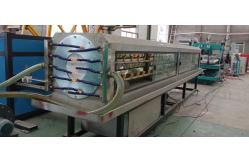

63-200mm PVC Double Wall Corrufated Pipe Machine , PE PVC Double Wall Corrugated Pipe Extrusion Line

Quick detial of corrugated pipe machine:

1. Suitable to U-PVC,C-PVC,M-PVC ,PE, PPR,PP,HDPE,LDPE pipe extrusion. 2. HDPE Double Wall Corrugated Pipe Machine/Extrusion Line with

various diameter and wall thickness, from 16-800mm.

Description of double wall corrugated pipe machine: 1. The plastic double wall corrugated pipe machine main composed of outer wall extruder, inner wall extruder, extrusion mold, corrugated forming machine, cooling unit, cutter, stacker. 2. Double wall corrugated pipe is mature product which has the

advantage of low weight, low cost, 3. Extruder:Adopt L/D ratio 38:1 screw for virgin material. Adopt L/D 33:1 screw for recycled material. We also have choice of twin screw and barrel for other material such PVC powder, PP powder, etc. Provide suitable extruder for different customer requirements. 4. Die Head and Calibration sleeve. Both outer layer and inner layer are extruded inside die head. Each

material flow channel inside die head is placed evenly. Each

channel is after heat treatment and mirrorpolishing to ensure

material flow smoothly. Also die head provides compressed air

between both layer.Calibration sleeve is used to cool inner layer

to form smooth and flat pipe inside. Pressure water flows inside

calibration sleeve to have good cooling effect. Vacuum is created

on calibration sleeve surface when producing big diameter pipe,

ensure inner pipe roundness. 5. Corrugator. Corrugator is used to place and move corrugated mould. Vacuum is

created to absorb outer layer into corrugated mould to form

corrugate shape. By moving corrugated mould, pipe is also pulled

out from corrugator. 6. Cooling tank. Cooling tank is used to cool pipe . 7. Cutter. Cutter controlled by Siemens PLC, double knife cutter. Equipped

with precise inspection device ensures the cutter accurately

placing at the correct position of double wall corrugated pipe.

Whole cutting process is accurate and fully automatic.

Technical parameters:

Usage:1. Building industry : electrical conduit & sanitary duct 2. Automotive industry: Fuel line & wiring harness 3. Medical industry : breathing tubes 4. Civil works industry : double wall cable conduit 5. Agriculture: single and double wall drainage pipe Machine display:

Tag:Corrugated pipe extrusion line double wall corrugated pipe machine

|

||||||||||||||||||||||||||||||||||||

| Product Tags: 200mm Corrugated Pipe Machine PVC Double Wall Corrugated Pipe Extruder Fully Automatic Corrugated Pipe Extruder |

|

High-speed PE plastic pipe production line for water supply systems |

|

Automatic PE Corrugated Pipe Making Machine For Drainage Systems, SJ65/33 HDPE Corrugated Pipe Extruder Machine |

|

HDPE Corrugated Pipe Extrusion Line for Drainage Systems,HDPE Corrugated Pipe Extrusion Line with Advanced Cooling System |

|

High-Efficiency SJ65/33 HDPE Single Wall Corrugated Pipe Extrusion Machine |

|

Fully Automatic HDPE Corrugated Pipe Extrusion Line , Cost-Effective HDPE Corrugated Pipe Manufacturing Line |

|

Customizable One Screw Polyethylene Pipe Production Line For Efficient Production |