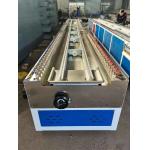

PVC Profile Production Line / Wood Plastic PVC WPC Profile Extrusion Machine

|

|

High Quality PVC Profile Production Line / Wood Plastic PVC WPC

Profile Extrusion Machine Quick detail:

1. PE WPC PVC Wood plate production line is our company successfully developed a composite self-invented technology, plate by adding pulverized plant fiber, the thickness adjustable, can be a single-or three-tier board, board width 915 ~ 1220mm, widely used in the construction template, furniture, decoration and other industries.

2. This machine uses the special designed screw and barrel , die and extrusion process to produce plastic and wood products , the series of products are : One step thick plastic and wood plate extrusion machine , one step plastic and wood profile extrusion machine , one step plastic and wood decoration plate extrusion machine , plastic and wood pelletizing machine and different kinds of plastic and wood dies.

Description:

1. The production line of electrical parts are used in the world famous brand products, combined with our company for many years plate equipment manufacturing technology and experience to make it more reliable and complete. Its production product surface smooth, bright and clean, size of the error is small, with a can nail can be planed, corrosion-resistant, fire retardant, and many other advantages.

2. Process Flow of pvc wpc board / panel production line: Raw material+wood power+additive→mixing → granulating → conical double screw extruder → sheet extrusion mould → cooling molding die → vacuum calibration tank → belt haul-off → cutter → rack → finished product inspecting&packing

3. WPC composite profile making machine can produce all kinds of profile, for example, window, door and door frame, pallet, cladding of outdoor wall, faciliry of ourside park, floor etc. Output profile is Wood Plastic Composite(WPC) or Plastic UPVC.

Technical Parameters:

Applications:

YF Series PVC WPC profiles extrusion line is mainly used in PVC WPC plastic steel doors and windows profile,window panels, perforated pipe threading and foam profile extrusion products. The production line according to the different requirements of customers and cross-sectional shape of the mold, you can choose the most suitable twin-screw extruder , and equipped with the appropriate vacuum form-ing . Cuttting and other auxiliary traction.

Competitive Advantage: 1. Good pre-sales and after-sales service 2. Engineers availiable to service 3. CE ISO9001 Certificate 4. Rich experienced engineers and skilled workes |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Plastic Profile Extrusion Machine Plastic Profile Extruder |

|

Customized Plastic Profile Extrusion Line Advanced Processing Technology Qingdao Port |

|

Customized Size Design Plastic Extruder Machine Low Noise |

|

PVC Profile Production Line, UPVC WPC Window Door Profile Extrusion Machine , PVC Extruder |

|

Manufacturing Process Of UPVC Profile , PVC Windows Profile Production Line , PVC Profile Extrusion Line |

|

PVC WPC Profile Machine WPC PVC Window Door Plastic Profile Production Line With Twin Screw Extruder |

|

PVC Window and Door Profile Extrusion Line , WPC Door and Frames Profile Making Machine, Plastic Coner Extrusion |