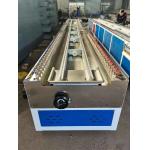

PVC Wall Panel Wpc Profile Extrusion Line , Wpc Profile Production Line

|

|

PVC Wall Panel Wpc Profile Extrusion Line , Wpc Profile Production Line

Quick detail:

1. The output capacity of wpc production line is from 150kg/h to 450kg/h for option. Haul-off machine is specially designed with particular up and down technology of our company, working stable, reliable and heavy duty force. Vacuum sizing tank having particular dig eddy low cooling system for cooling and sizing easy for high speed extruding necessary. The action of cross direction saw cutter keeping synchronous with haul-off controlled by import PLC controller, reasonable design, running stable.

2. Our CE approved WPC PVC profile extruding machine is high technical and easy to operated. It can be used to produce various WPC products, such as WPC foam board, WPC floor, WPC door, ect. WPC products is made from PE/PP or PVC and wood powder and additives. It is a new generation of greenenvironmental material and very popular in the world at present. WPC product have both wood and plastic double properties, and it's mechanical performance is better than wood. It also have the features of water-proof ,fire-resistant,anti-corrosion,anti-moth,100% recycled.

Description:

1. Machine's Introduction:Needless granulating of materials, mixed with wood powder, the material can be directly used to extrude wood-plastic profiles. Suitable material: PE, PP + wood powder, PVC + wood powder. Applicable for producing salver, packaging box board and decorative sheets, etc.

2. Our wpc machine has features of low consumption,low noise,stable running.This wpc machine include:extruder,mould,vacuum calibration table,haul-off machine,cutter and stacker.The extruder of wpc machine adopt special wpc screw and barrel for extrusion.With different mould, wpc machine can produce wpc products with different shapes.

3. Plastic Ceiling Machine- PVC/WPC Ceiling/ Window Profile Extrusion and Making Machine is applied to produce PVC ceiling panel, PVC wall panel,PVC ceiling tile the hollow board like that. This production is composed of conical twin-screw extruder, vacuum calibration table, haul-off, cutter and stacker. Change different extruding mould,this machine can also produce PVC door & window profiles, foamed special shaped materials profiles, decoration plate material, profile and multi-hole wire plastic products, etc.

Applications:

WPC profiles production line is the manufacture facilities of PVC plastic profile materiles, including window and door series profile, plate, sheet, foamed profile and foamed ornament plate.

Specifications:

Competitive Advantage:

1) We give you suitable suggestions according to your actual need. |

|||||||||||||||||||||||||||||||||

| Product Tags: Plastic Profile Production Line Plastic Profile Extruder |

|

Customized Plastic Profile Extrusion Line Advanced Processing Technology Qingdao Port |

|

Customized Size Design Plastic Extruder Machine Low Noise |

|

PVC Profile Production Line, UPVC WPC Window Door Profile Extrusion Machine , PVC Extruder |

|

Manufacturing Process Of UPVC Profile , PVC Windows Profile Production Line , PVC Profile Extrusion Line |

|

PVC WPC Profile Machine WPC PVC Window Door Plastic Profile Production Line With Twin Screw Extruder |

|

PVC Window and Door Profile Extrusion Line , WPC Door and Frames Profile Making Machine, Plastic Coner Extrusion |