High Performance Double Screw Plastic Profile Extrusion Line Fully automatic

|

|

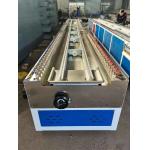

High Performance Double Screw Plastic Profile Extrusion Line Fully automatic

Quick detail:

PVC profile extrusion line is mainly used to produce PVC profile like PVC window, PVC door, PVC ceiling, and PVC wall board PVC floor and so on.

Description:

1. The working process of PVC Ceiling Production Line:

2. This machine is mainly used to produce PVC window & door profiles, PVC trunking profiles, PVC ceiling profiles, PVC panel, PVC board and so on. This PVC profile production line adopts advanced design concept to ensure the efficient extrusion of PVC material, combined with the unique concept of plasticization screw design to ensure uniformity of plastic extrusion, high capacity production.

3. This machine uses the special designed screw and barrel , die and extrusion process to produce plastic and wood products , the series of products are: One step thick plastic and wood plate extrusion machine , one step plastic and wood profile profile extrusion machine , one step plastic and wood decoration plate extrusion machine , plastic and wood pelletizing manchine and different kinds of plastic and wood dies.

Applications:

Profiles for the building industry

Specifications:

Competitive Advantage:

1) We give you suitable suggestions according to your actual need. |

|||||||||||||||||||||||||||||||||

| Product Tags: Plastic Profile Production Line Plastic Profile Extruder |

|

Engineer Aviliable To Service Plastic Profile Extrusion Line with 38 Moaia Screw Material and SJSZ65X132 Screw Diameter |

|

Customized Size Design Plastic Extruder Machine Low Noise |

|

Profile Product Plastic Extruder Machine The Future of Manufacturing |

|

Extruding Machine for Plastic Profiling Machinery and User-Friendly |

|

Customizable Plastic PVC Profile Extrusion Line for Different Profile Product Specifications |

|

Sell Plastic Profile Production Line with 380V 50HZ Voltage |