Double Screw Wood Plastic Pvc Foam Board Production Line High Speed

|

|

Double Screw Wood Plastic Pvc Foam Board Production Line High Speed

PVC Foam Board:

it has such characteristics as high impact resistance , high rot resistance , high temperature resistance , non-toxic, smooth surface , light , easy to thermoform , etc.

Applications: such as wire plate , environment protection material , venting equipment , semiconductor equipment , etc.

Production scope: thickness 1-30mm , width 3000mm(under)

Description:

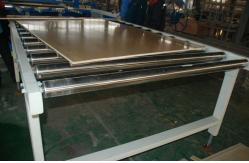

1. This unit adopts special designed SJZ92 conical twin screw extruder, uses DC speed regulator, imported world famous brand temperature controller, has the advantages of large speed regulating scope, accurate temperature control, easy and reliable operation. The auxiliary units consist of vacuum foamed stand, haul-off, cutting machine and stacker, etc. It is equipped with large forced cooling device to ensure good foamed result. The caterpillar type haul-off adopts précised reduction and frequency inverter, features reasonable structure; large hauling force and stable haul off. The cutting machine has the characteristics of reliable and precise working, accurate cutting, etc. The stacker is matched with movable trolley and special designed rubber protection shield, has the advantages of damage free to the product, easy and convenient operation, etc. The auxiliary units are able to use the PLC control, which is stable and reliable.

2. PVC foam board making machine are applied in PVC powderas raw material to produce kinds of profile and board. Adopting our company’s special design and unique processing, these lines can produce different proportion (0.55-0.95) profile wood plastic products to meet customer’s needs. With different products, we can match different performance twin extruder or single extruder which equipped with auxiliary devices such as vacuum forming machine, haul-off and cutting machine, loading shelves to optimize its capacity. By using moulds which are specially designed with customer’s products, customer can produce the products that they need.

Applications:

For door board, wall panel, decking, etc.

Specifications:

Competitive Advantage:

1. good after-service 2. spare parts are free 3. guarantee:one year or according to customer’s requirement. 4. advanced technology and best quality 5. international certification standard. 6. our engineer help and teach customer to test the machine.

|

||||||||||||||||||

| Product Tags: Foam Sheet Extruder PVC Foam Board Production Line |

|

Double Screw WPC PVC Foam Board Machine For Door 1220 - 1600mm |

|

90mm Screw WPC PVC Foam Board Machine Sound Insulation |

|

Plastic Furniture Board Making Machine WPC PVC Crust Board Production Line |

|

3 - 30mm PVC Foam Board Machine Furniture Advertisement Board Making Machine |

|

Furniture Door PVC WPC Crust Foam Board Making Machine With Twin Screw Extruder |

|

UPVC WPC Furniture Board Making Machine PVC Foam Board Production Line CE |