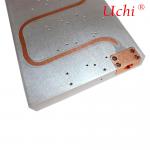

150x200x25mm Copper Liquid Cold Plate From Winshare Thermal

|

|

Copper Liquid Cold Plate From Winshare Thermal

Using friction welding for heat sinks can resolve the technical

bottleneck of joining two or more materials to form

high-aspect-ratio ultra-wide products. Moreover, its tooling cost

is lower with a short cycle time and higher stability. Based on the

data that has been accumulated by our R&D team in the long run,

has developed several standard materials and we keep enhancing the

database of our

The following is about Laser equipment double tube inlet-outlet

cold plate laser machines use water cold plate related, I hope to

help you better understand aluminum skived fin heat sink cnc

machined skiving fin heat sink.

In a world of compact designs with increasing power densities, cold plates are satisfying demanding contact cooling requirements in applications as diverse as high-powered electronics, power generation, medical equipment, military and aerospace, and lasers. For high watt densities, when air-cooled heat sinks are inadequate, liquid-cooled cold plates are the ideal high-performance heat transfer solution. Yuanyang is at the forefront of cold plate innovation, offering three different cold plate technologies . With full custom design and build capabilities, plus over 15 standard product lines, Yuanyang can solve all your thermal challenges Custom Cold Plates Custom Cold Plates Custom Cold Plates for Mission Critical Power Electronics Cooling The drive towards higher power and more compact packages is making liquid cooling a necessity in many applications. Partnering with Original Equipment Manufacturers (OEMs), Yuanyang supplies custom cold plates for electronics cooling and other applications where high performance and high reliability are essential. Our cold plates, which include vacuum-brazed and Friction Stir Welded (FSW) performance-fin cold plates and chassis, flat tube cold plates, and tubed cold plates,

Product designing and manufacturing of New product optical fiber water cold plate double fiber laser equipment water cold plate

Every products of heat sinks needs several process including the drawing design, CNC machining, friction welding stir, soldering, assembly, skiving and extrusion, Testing and finally turn to the step in the surface treatment.

Product application of New product optical fiber water cold plate double fiber laser equipment water cold plate

Our heat sinks and water cold plates has been utilized in many of fields, including transportation, CPU computer, servers, Led light, Laser equipment and air condition and so on as long as any electrical product that generate the heat.

So when you are designing the thermal heat sinks or any radiators, there must be some of them may be met your requirement.

Packing details of New product optical fiber water cold plate double fiber laser equipment water cold plate

All the heat sinks, water cold plates and heat pipes are packed in the EPE foam and in the carton, the carton itself has the strong protection using the wooden frame for it and finally utilize the Packaging transparent film as it is water proof, some of the larger heat sinks or water cooling plate may adopt the wooden carton due to the special demanding, wooden box inside has the thick EPE that offer great protection from inside and outside knocking!

|

| Product Tags: Customized Liquid Cooled Cold Plates SMC Approved Liquid Cold Plate OEM Cold Plate Liquid Cooling |

|

Industrial Equipment Aluminum Profile Copper Tube Radiator High Power Water Cooled Plate Radiator Custom Processing |

|

High power laser cooling water plate, water cooling plate radiator customized processing |

|

Liquid Cooled Cold Plate For Inverter Good Heat Dissipation |

|

China Pressed Tubed Liquid Cold Plate Copper Tube |

|

Aluminum Optical Fiber Chill Plate Friction Welding Liquid Cold Plate |

|

Water Cold Plate Heat Sink Embedded Copper Tubes Water Cooling Heatsink 120(W)*36(H)*210(L)mm |